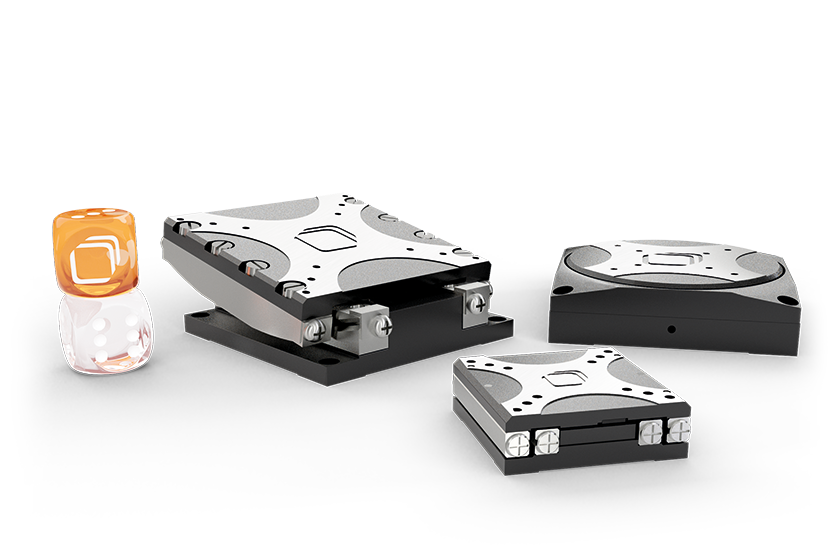

Facilitated by their unique piezodrive technology, their stiff mechanical design, and the application of crossed roller bearings, ambient and vacuum nanopospositioners are capable of moving and placing loads of up to several kg on the nanometer scale.

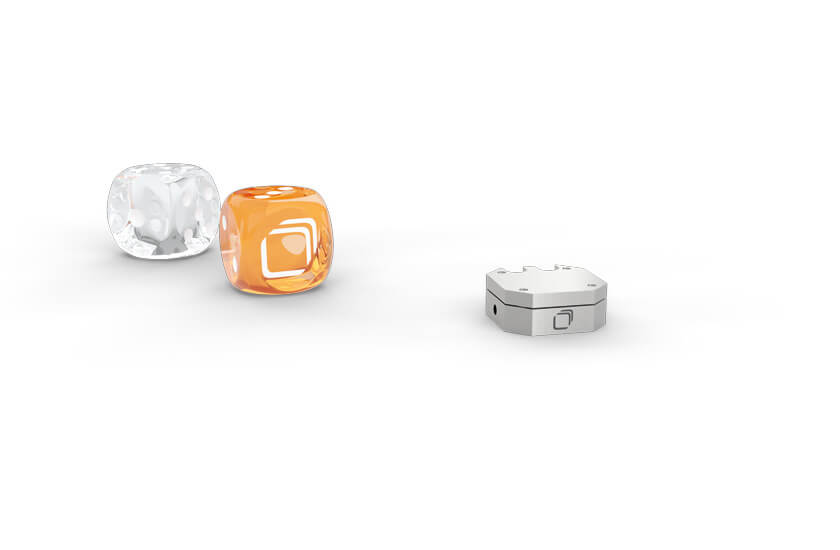

Ambient and Vacuum Nanopositioners

piezo-based nano drives for atmospheric and vacuum conditions

attocube’s nanopositioners all incorporate a piezoelectric motor to achieve motion with nanometer precision, and are available in a variety of different materials for the body, sizes and options depending on the application of the customer.

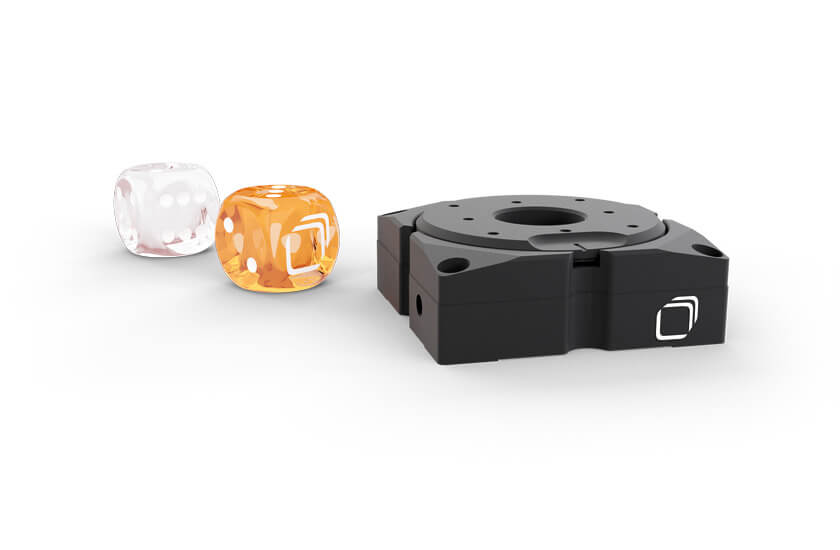

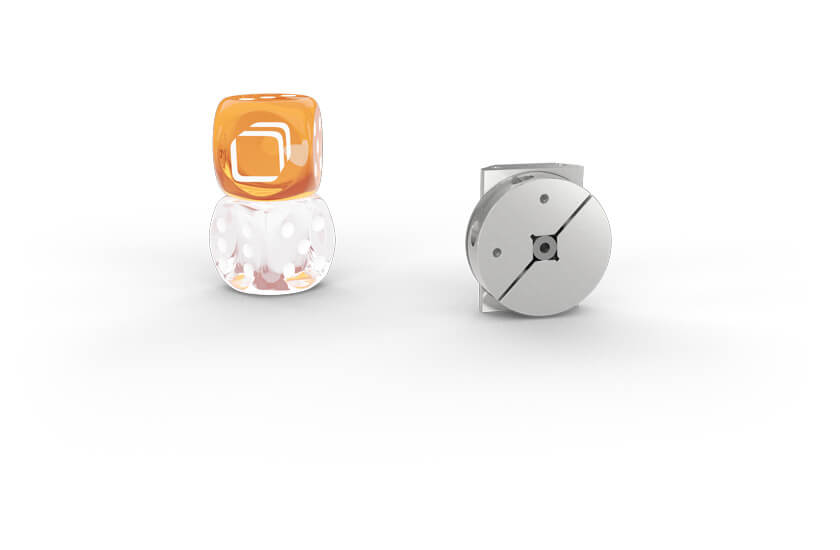

For our bearing-based EC* series positioners, light weight and strong aluminium is used for applications in atmosphere, while a stainless steel housing is compatible with vacuum conditions up to UHV. The AN* series is suitable for special requirements such as limited space or non-magnetic demands, and, therefore, built up from titanium or beryllium copper.

The product finder takes the hassle out of finding the nanopositioner for your setup by sorting the entire portfolio according to the specifications important to you.

High Loads

Closed Loop Control

In conjunction with the three-axis drive electronics AMC100, ambient and vacuum nanopospositioners are capable of a closed-loop positioning resolution of 1 nm (1 μ°) while providing travel velocities of up to 4.5 mm/s (10°/s). A position repeatability of 50 nm ( 50 μ°) tops off the specification of these nanopositioners.

Vacuum Compatibility

Ambient and vacuum nanopospositioners are dedicated for operation at room temperature and pressures ranging from ultra high vacuum to ambient. All stages are either available in anodized Aluminum or stainless steel, satisfying both optical and UHV applications.

Materials & Life Expectancy

For ambient and vacuum nanopospositioners special emphasis was put on both life endurance and cost effective manufacturing. The room temperature optimized drive mechanism, combined with the choice of aluminum or stainless steel as main body material, enables a significant cost reduction, while achieving a life span about 500,000 cycles.

0 Positioners

with your choice

Type of Positioner

Type of encoder

Minimum Required Pressure

Direction of Movement

Min. Travel Range

Material