Quality Assurance & Quality Control

OEM components for QA&QC

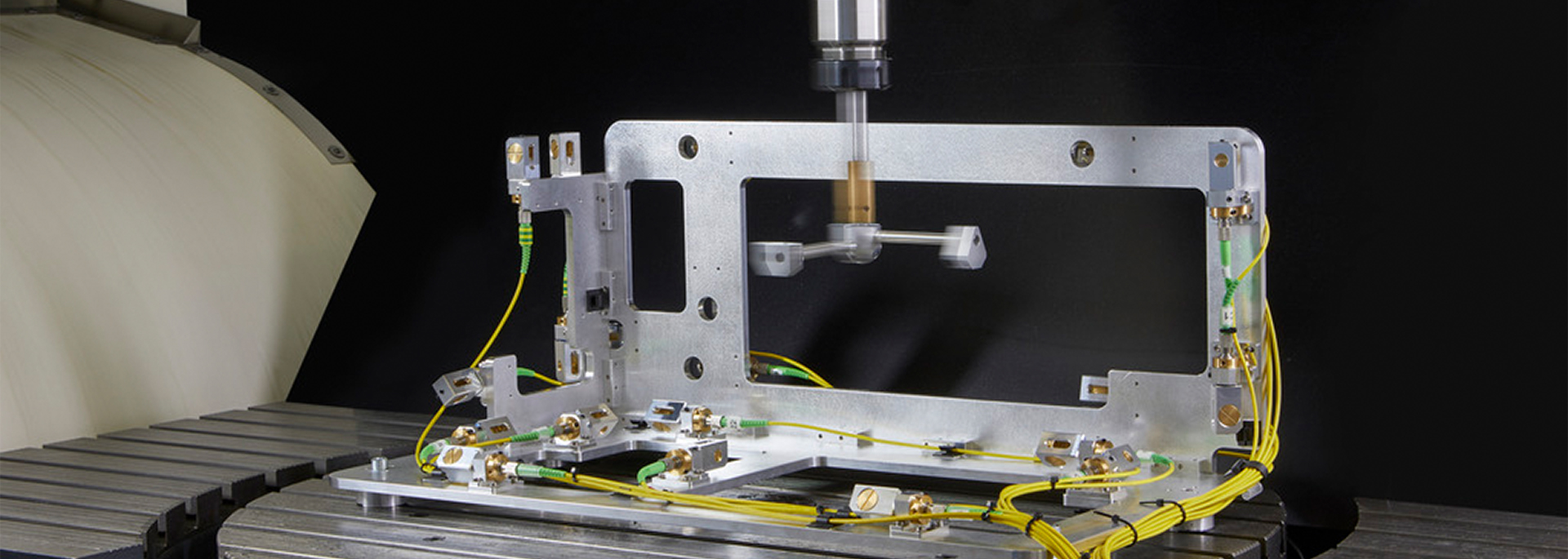

Quality control and quality assurance are essential for any manufacturing process to enable the best quality of manufactured products. Increasing requirements on manufacturing accuracy, processing time, and space conditions ask for smaller, faster, and more precise sensors and actuators. attocube’s interferometers and nanopositioners are used for moving and measuring directly on the work piece, e.g. wafers, circuit boards, microelectromechanical systems (MEMS), cantilevers, or optical components like lenses or mirrors.

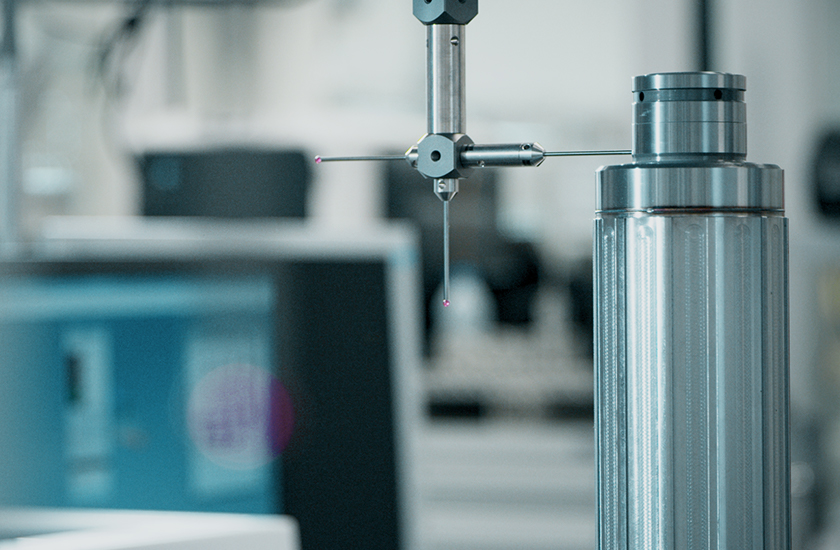

While nanopositioners are capable of aligning the setup with nm precision, the interferometric displacement sensor may be used to detect any movements or vibration for travel ranges over several meters down to nm accuracy. The interferometers are also used to calibrate machine tools, linear axes, or measurement machines, like coordinate measurement machines (CMM), microscopes, or computer tomography systems, or as a sensor for closed loop feedback.