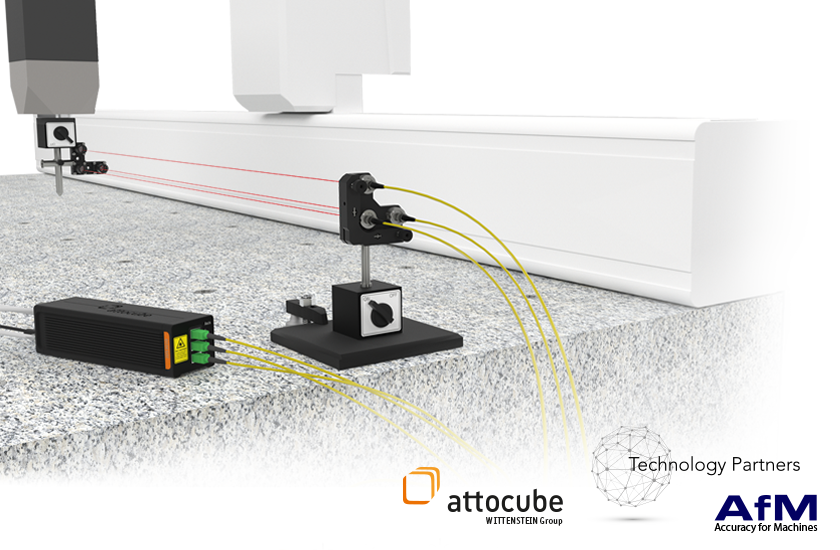

Motion Tracking in Coordinate Measurement Machines

interferometer for motion tracking in coordinate measurement machines

Coordinate measurement machines have the highest requirements towards precision, accuracy and repeatability. It is essential to measure the geometry of objects correctly for a proper quality control. This determines manufacturing accuracy, offer knowledge on the tribological phenomena in order to solve or reduce material failures or malfunctions. CMMs normally require an accuracy in a sub-micrometer range, while the calibration and the machine-integrated control need an even higher level of accuracy.

attocube's solution

The IDS3010 interferometer sensor provides certified accuracy below 1 ppm for continuous measurements from 0 up to 5 meters – suiting the challenging requirements of CMMs. Overshoots in the nanometer range and angular deviations can be detected, visualised and used for sophisticated error compensations (AxisCalibration Software).

Furthermore, the compact design of the IDS3010 and the versatile sensor heads fits an extensive number of different machine-integrated applications.

Displacement Sensor IDS3010

- certified accuracy < 1ppm

- working distance 0 mm to > 5 meters

- target velocity up to 2 m/s

- sensor head diameter 1.2 - 15.5 mm

- simultaneous multi degree freedom measurement

- AfM standardized & automated calibration software

On-demand webinar

"Standardized Calibration of CNC Machines"