Accuracy Evaluation

motion analysis and accuracy determination

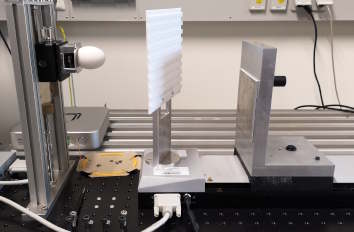

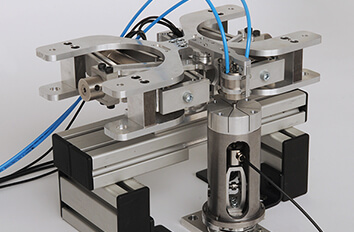

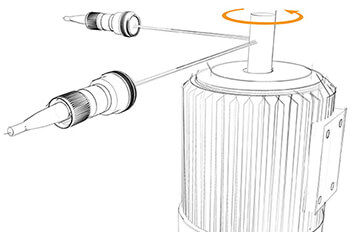

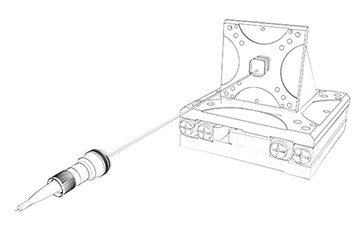

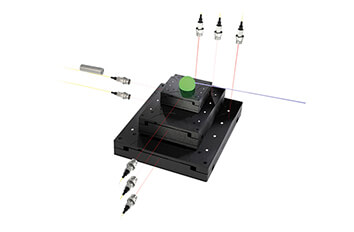

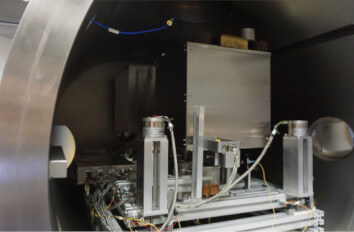

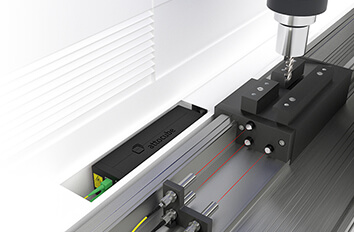

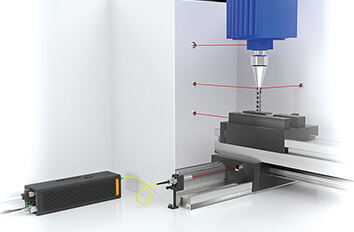

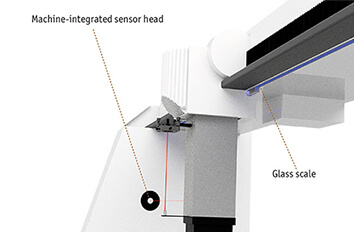

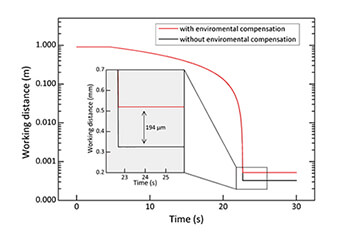

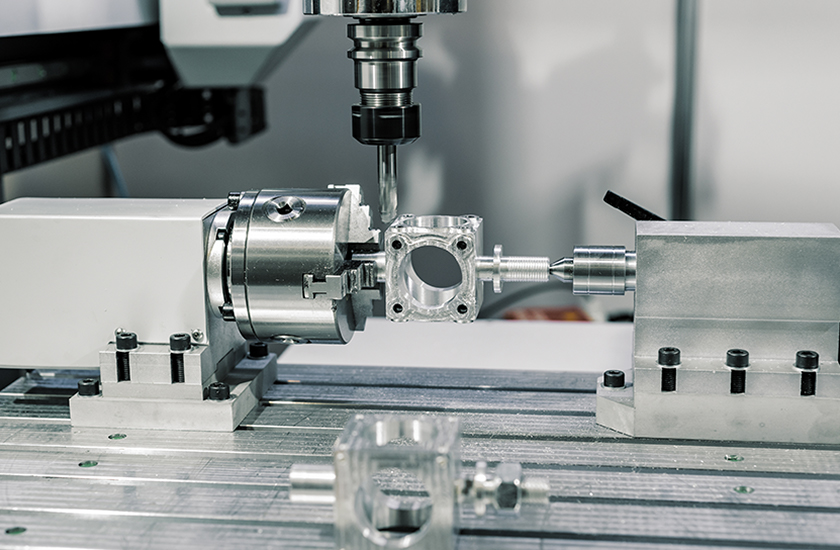

For optimizing the motion of production machines and machine tools, it is necessary to know the exact position of moving parts and machine axes at high speed. This is essential for fast running machines, like pick-and-place applications, and general machines for manufacturing and quality control of printed circuit boards (PCB). attocube's interferometers are capable of detecting the amplitude and frequency of the smallest vibrations and overshoots. This information is necessary to know the attenuation of an oscillation for optimizing production and quality processes. In other machine tools, like CNC turning machines, the interferometer can also detect the frequencies and runout of fast running spindles. In contrast to glass scales in coordinate measurement machines which can only measure the displacements at the bridge but not at the touch probe itself, the laser interferometer can focus on the touch probe itself to detect error motions of the machine. For defining official specifications, manufacturers of machines need to define a tolerance range based on varying external conditions. Such a specification measurement includes the determination of the geometric errors, the positioning errors, and the thermal errors. Besides static position values, also the dynamic position values during motion need to be checked. To specify the manufacturing or measurement accuracy of machine tools, measurement tools, or precision measuring centers, the IDS3010 is used as a reference device as it is one order of magnitude more accurate than the machine itself.