Material Deformation

detection on deformed surfaces

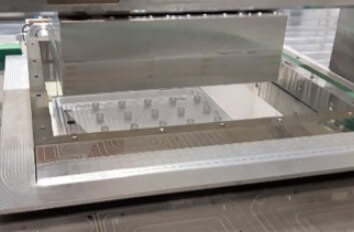

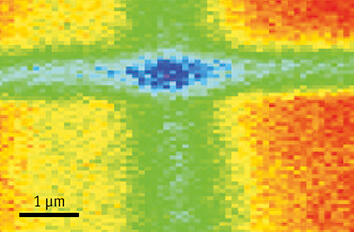

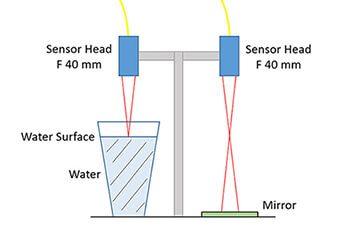

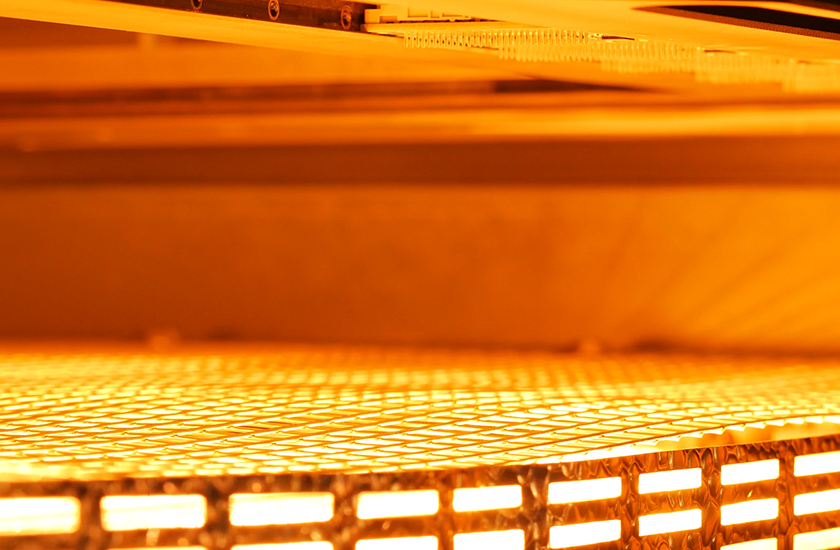

In high precision applications, i.e. precision engineering and quality engineering, the accuracy of machines and tools depends on well-defined shapes of the involved components and materials. Variations of temperature in machine halls and heat generated moving parts of the machine tools lead to material deformation of spindles, for example. There are many methods and models for compensating this resulting thermal error. These methods and models require real data from the machine's deformation that can be captured by attocube's laser interferometers. Besides the thermal influences, the work piece experiences with multidirectional forces resulting in strain that leads to material deformation of the work piece. In some production methods, this deformation needs to be checked to analyze the production step or to optimize the manufacturing quality. This is especially relevant in semiconductor industries for the lithography process. In some process steps, a wafer chuck is used for holding the wafer in a set position and shape under high vacuum or ultra-high vacuum. attocube's interferometers can be used for measuring the material deformation down to the nanometer of the wafer chuck but also by the wafer itself after those production steps.