Testing of QC Components

analysis of mechanical, electrical and optical properties

Integrated photonic or trapped ion quantum computing are two of the most promising approaches to create powerful quantum computers. The architecture of these computing systems is highly complex, and many devices need to operate reliably in extreme environments. In order to prevent costly system failures, the various mechanical, electrical and optical components or subassemblies need to be tested in advance. To successively reduce the risk, testing procedures often start with testing in clean room conditions and end with extensive thermal vacuum chamber testing, to simulate ultra-high vacuum and changing temperatures.

Independent of the environmental challenges, the testing procedures require the highest precision. Optical and optronic components like fibers and detectors must be aligned with submicron repeatability and mechanical deformations due to temperature changes need to be detected with nanometer precision.

attocube's solution

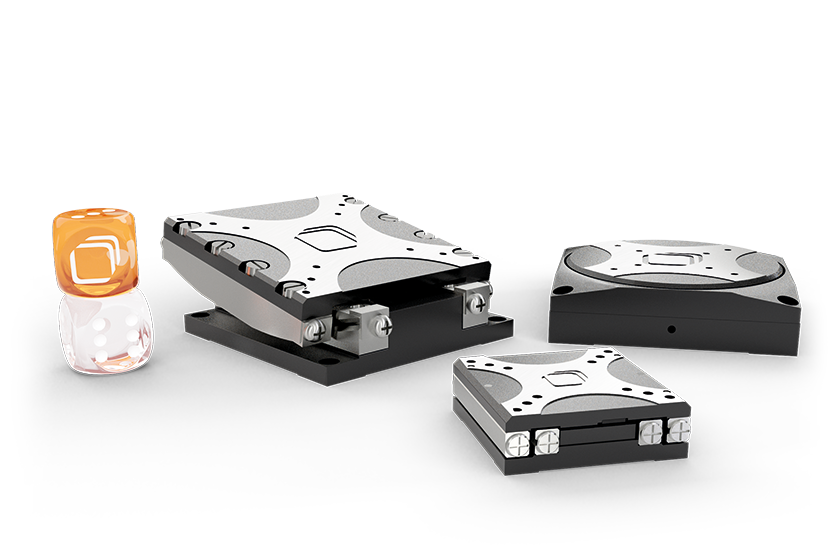

In addition to cleanroom and vacuum compatibility down to 10-11 mbar, attocube´s nano-positioners offer the required precision and different stages can be combined to allow multi-axis movements.

For even higher precision the IDS3010 interferometer can be used as the closed-loop feedback sensor for the positioners. Furthermore, the IDS3010 can be used individually for thermal expansion and vibration measurements on retroreflectors, or in order to avoid additional mass, directly on high reflective materials.