Displacement Sensor

one dimensional displacement measuring interferometer with nanometer accuracy

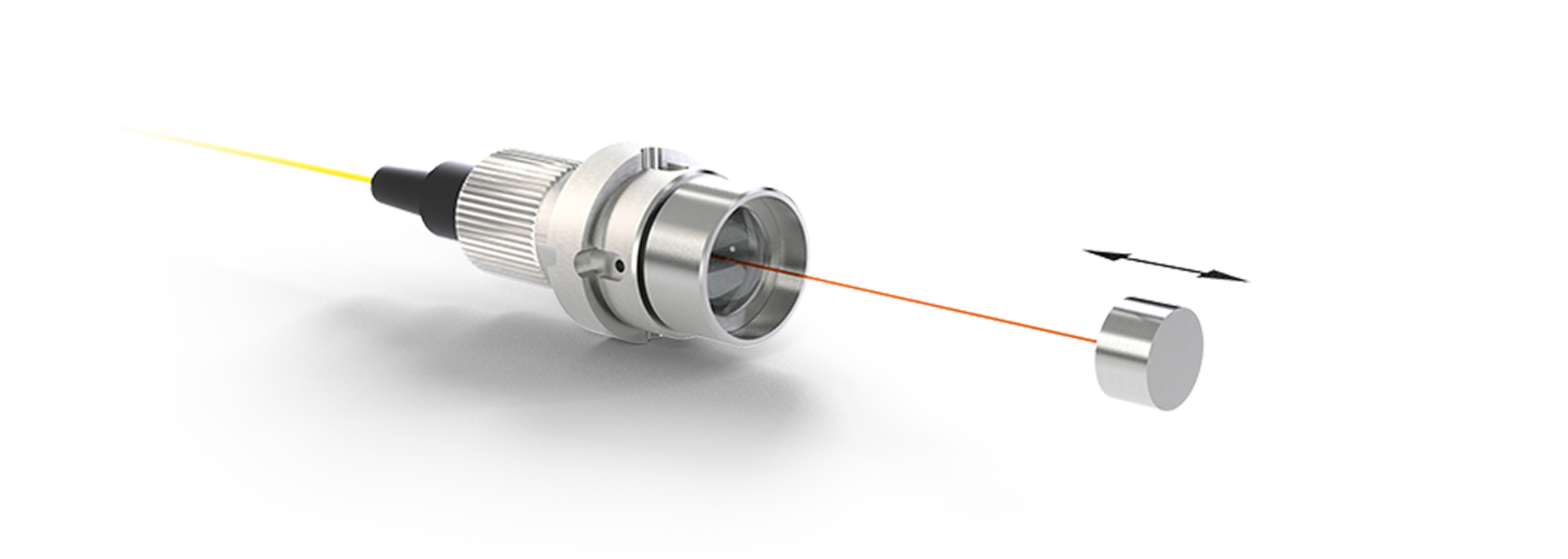

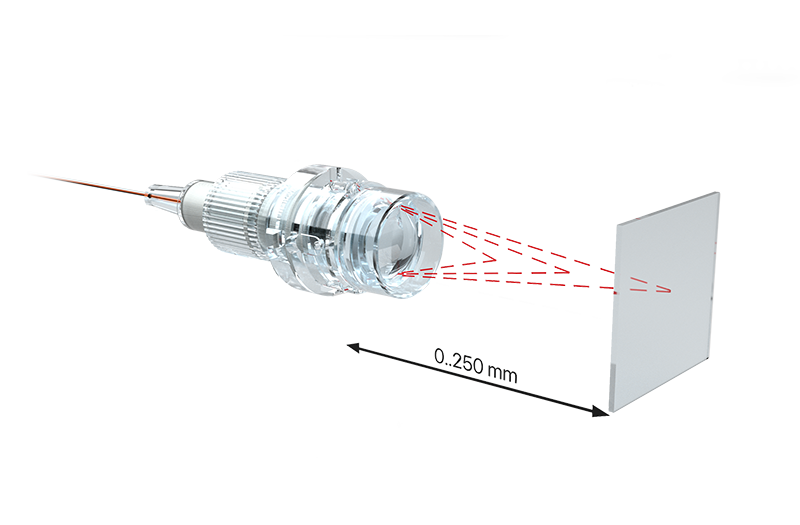

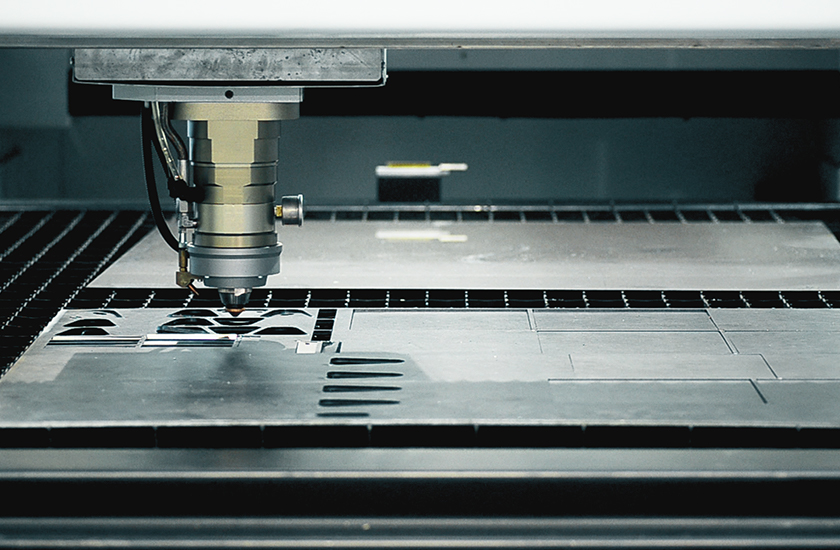

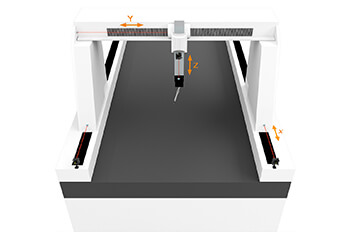

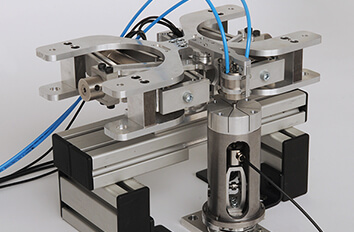

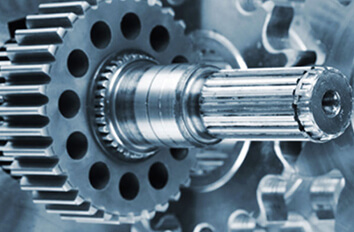

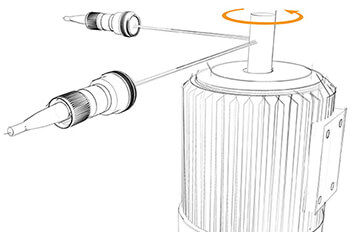

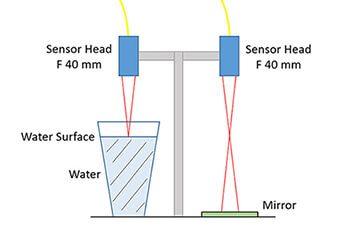

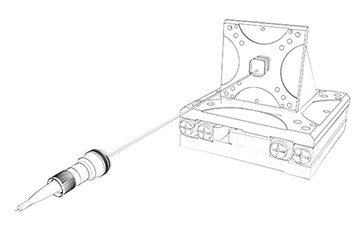

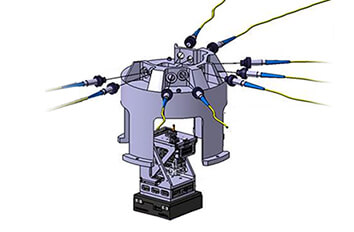

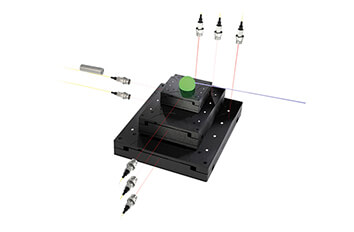

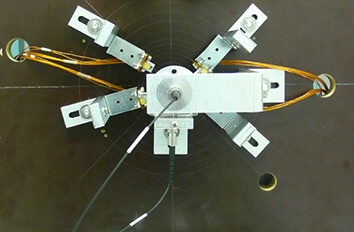

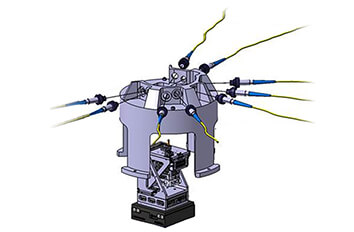

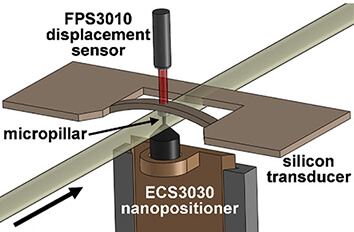

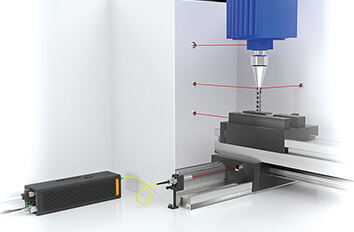

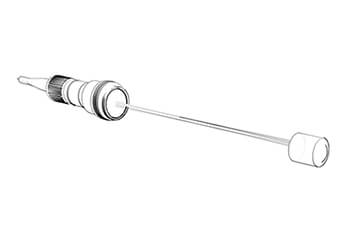

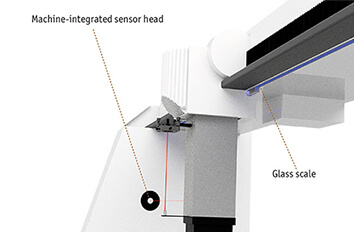

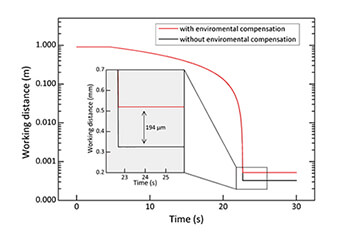

attocube‘s laser displacement sensor measures linear motions of a target. The miniaturized interferometer device is capable of measuring in three axes. Based on a Fabry-Perot Interferometer, it enables large working distances ranging from a few millimeters to several meters. The laser interferometer performs most accurate measurements on different materials and geometries. The patented, fiber-based technology of attocube provides a modular measurement setup and extremely compact laser sensor heads. This technology also enables vibration measurements, runout measurements of rotations, or calibration of machine tools. The position signal can be used as the input for a closed-loop positioning system.

Fields of Applications

Customer Feedback

Prof. Dr. M. Tajmar

Institute for Aerospace Engineering, Dresden University of Technology, Germany

The noise and stability of the attocube FPS interferometer is up to two orders of magnitude better than the second best system on the market. The installation and use of the sensor was so easy that we could obtain high quality measurements within two weeks after they first arrived at our lab – thanks to the great support from attocube.

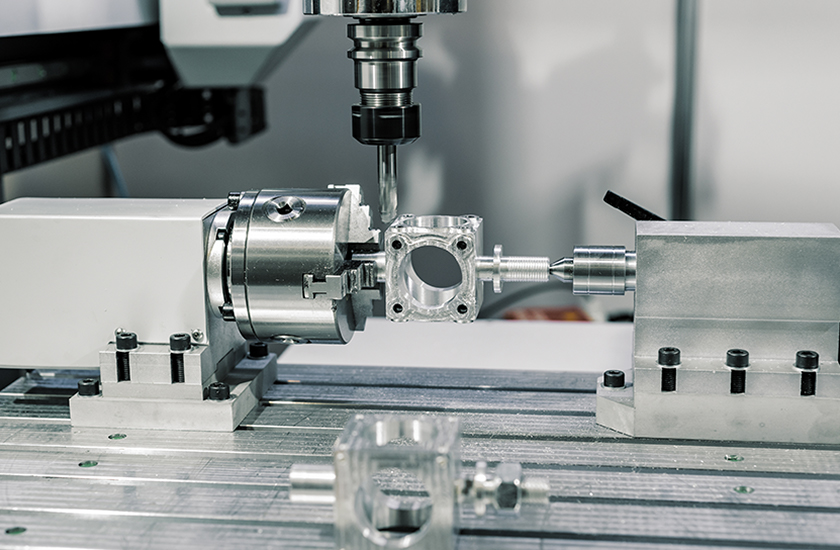

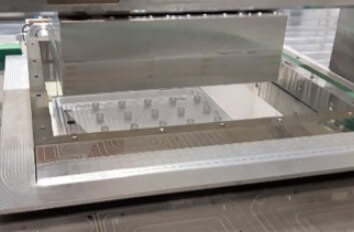

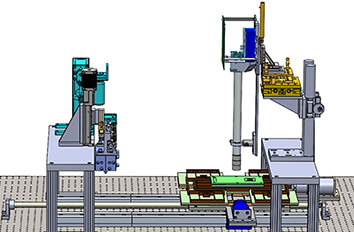

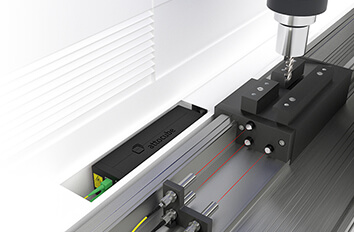

Dipl.-Ing. Nanxi Kong

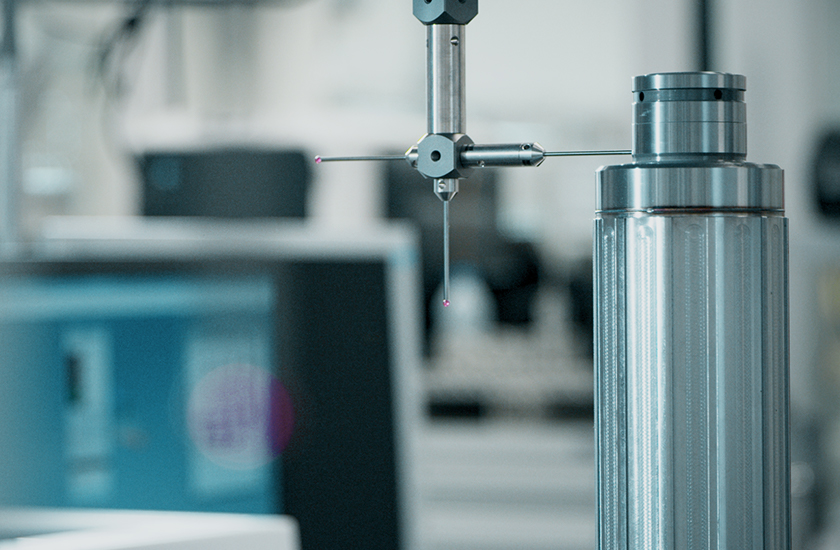

Institute of Production Engineering, Helmut Schmidt University, Hamburg Germany

The motion of a feed unit for micro manufacturing needs to be very precise and accurate. As linear encoders allow only the measurement of the position along one axis, the attocube FPS interferometer can be easily configured to directly measure the position of the tool center point at the feed unit in all directions.

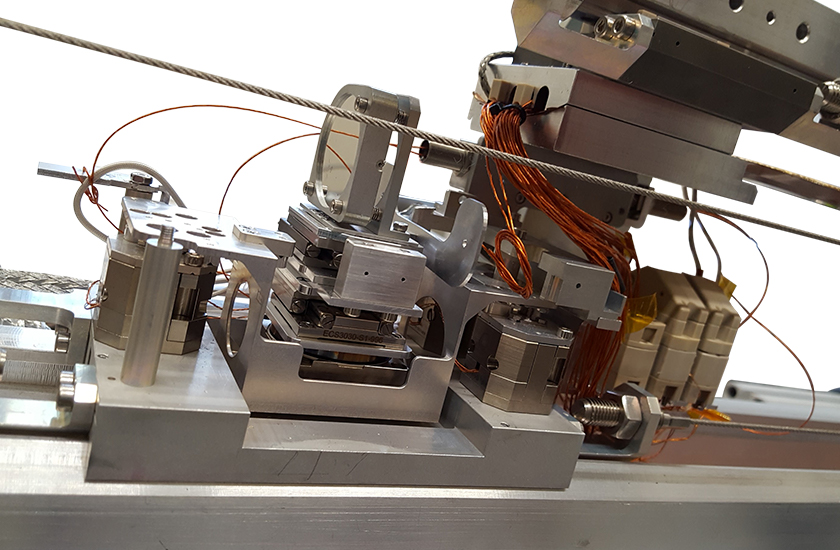

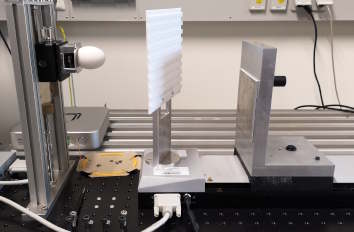

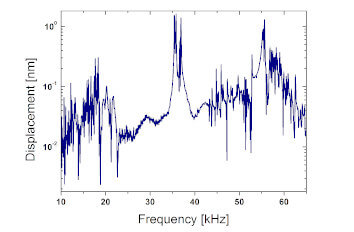

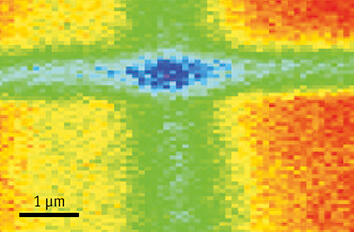

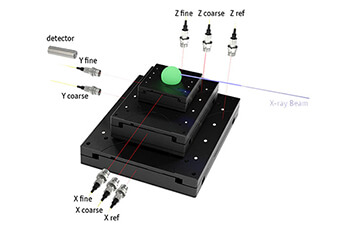

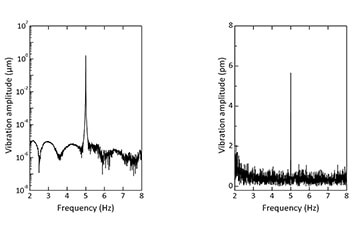

Nicolas Stübe, Dr. Alke Meents

DESY/suna-precision GmbH, Hamburg, Germany

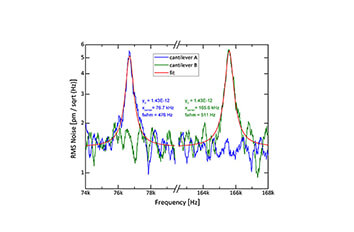

Thanks to the fast adjustment and precise sub-nanometer resolution of the sensor, we`re able to easily identify the trajectories and eigen frequencies for the optimization of flexure-based components. The combination of the digital interfaces with our motion control system allows most accurate closed-loop control for scanning applications. With the closed-loop integration of the IDS3010 in our X-ray microscope by the end of 2015, we feel confident to get the first 3-D tomographic pictures of biological samples with a resolution of 20 nm within by beginning of next year.

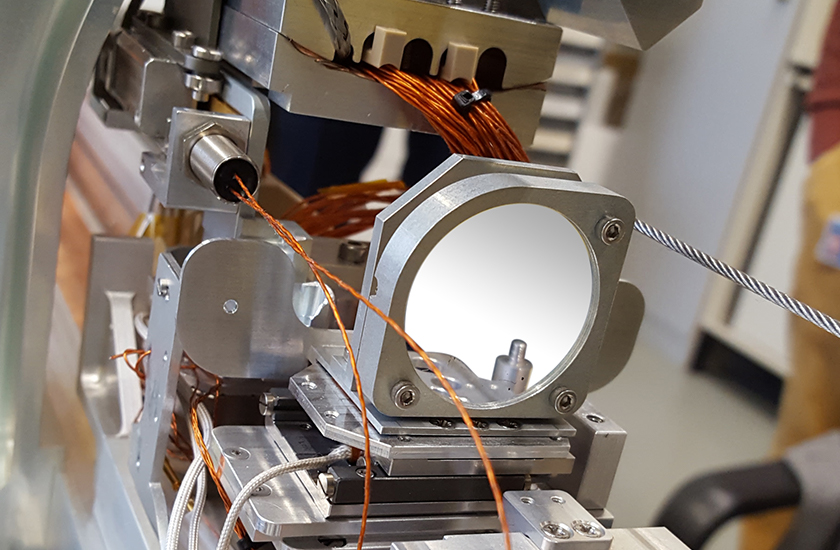

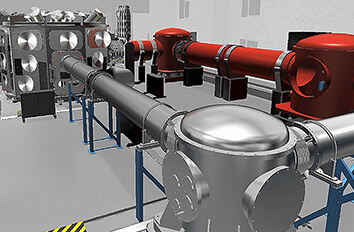

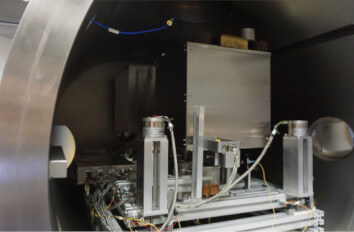

Dr. Stefan Kubsky

Synchrotron Soleil St. Aubin, France

An intense and ongoing scientific exchange with the attocube-development team permitted us to obtain new functionalities and highest precision. Our system, being inherently non-standard, profits greatly from the compactness and modularity of the sensorheads. We rapidly managed to file a patent application implying interferometric metrology.

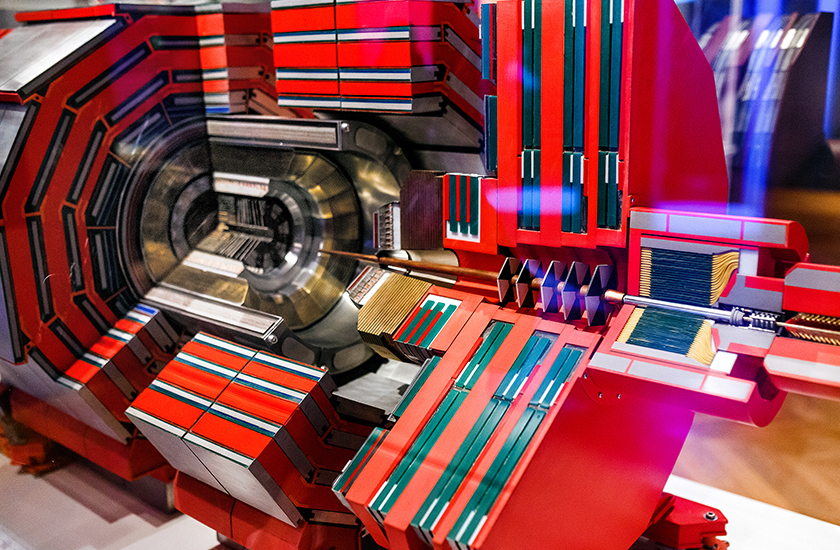

Dr. T. Zickler

CERN / Magnetic Measurement Section, Geneva, Switzerland

Before purchasing a laser interferometer, we were not sure about the applicability of the interferometer for our requirements. During the short testing phase, we became familiar with the interferometer and its operation. While using the sensor for the intended application, we verified the advantages of the device and decided for purchasing it.

Dr. Jonathan Kelly

Diamond Light Source Ltd., Didcot, UK

The WAVE software has proved very useful in characterising and commissioning the interferometers on our P99, Ptychography test set-up. It enabled easy measurement and identification of the mechanical resonances of the system. It is also ideal for sampling positions at a wide range of rates for use in other applications.