Lens Inspection Metrology

curvature measurement & position tracking

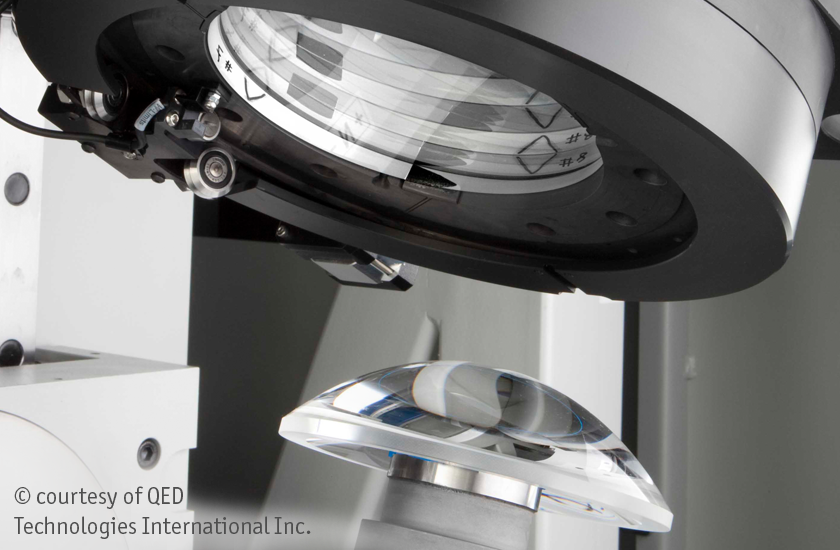

Metrology is a critical part of the optics fabrication process. The fabrication of high quality, advanced optics is often seriously restricted by the lack of accurate metrology - “If you can’t measure it, you can’t make it”. Extensive metrology enables higher efficiency, flexibility, and reliability of any optics manufacturer. Non-contact optical probes, usually based on confocal principle or phase measuring interferometry are capable of measuring even complex optics geometries, like e.g. aspheric lenses.

However, the metrology systems have to measure ever bigger lenses, with increasing accuracy and more comprehensive information. This requires multiple measurements with changing orientation of the probe or lens and highly accurate alignment. Therefore, a sensor allowing high precision position tracking of the relative movements between the probe and the lens is needed.

attocube's solution

attocube´s IDS3010 interferometer sensor offers ultra-precise and continuous displacement measurement over high ranges, while the modular design offers simultaneous 3 channel measurements. Furthermore, the compact and fiber-based sensor heads can be flexibly integrated in any metrology system.