Laser Beam Adjustment

in metrology and inspection tools

During the metrology process in the wafer production the light or laser beam path has to be precisely and continuously adjusted to perform control over the wafer surface in order to detect imperfections and to provide detailed information on the wafer´s quality.

There are various inspection methods: The un-patterned wafer inspection identifies particles and pattern defects and links those to a specific position on the wafer, while the patterned wafer inspection identifies geometry imperfections via the comparison with a “golden” dye. Lastly, the reticle inspection helps to identify single defects on a wafer reticle and is usually performed by using UV illumination.

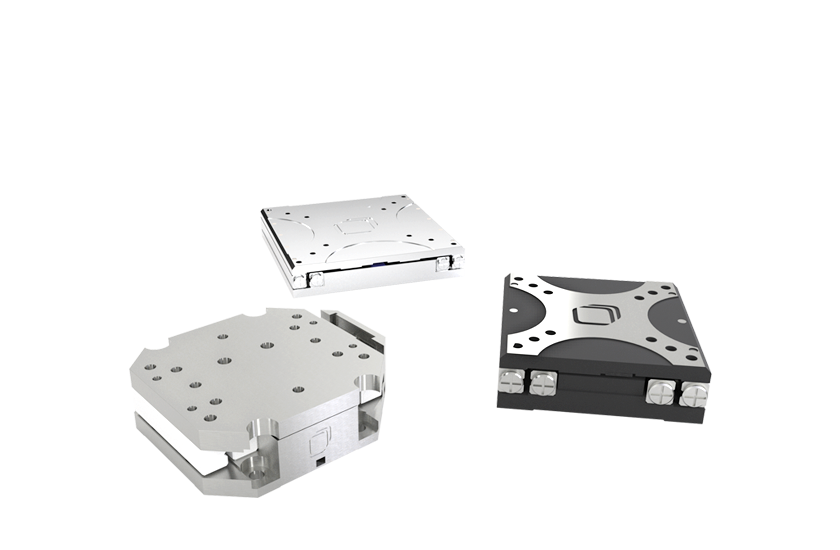

attocube's solution

attocube nanopositioners are designed for the use in ultra-precise motion applications in extreme conditions and offer superior accuracy, repeatability and resolution. This makes them the perfect components for continuous and stable beam alignment within the metrology process.