Large Scale Multi-Axis Motion Control

for flat panel display (FPD) processing stages

The chase for higher pixel density, brilliant color quality, more compact devices, and maximum energy efficiency made the OLED technology conquering the flat panel display market.

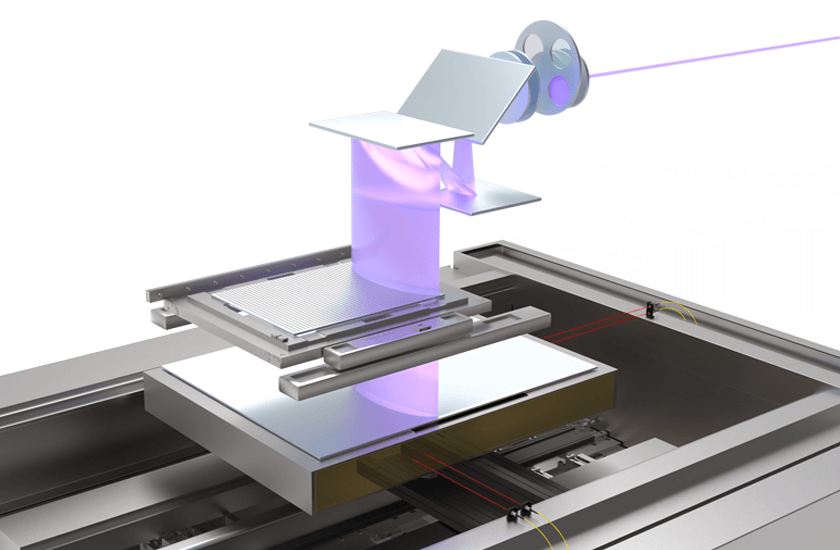

The high resolution OLED displays consist of millions of electrical circuits controlling the light emission. These circuits contain µm sized elements which are created utilizing lithography. In contrast to typical semiconductor manufacturing the structures are not created on small silicon wafers, but on large glass panels (1.5 x 1.8 m). During the lithography - and also inspection processes, these panels need to be moved by long range XY motion stages with maximum precision in order to ensure highest output and quality. While travel ranges are relatively large, movements need to be tracked with sub µm resolution.

attocube's solution

attocube´s interferometer sensor IDS3010 enables continuous multi-degree of freedom measurements from 0 – 5 meters with ultimate precision. Multiple real-time interface options allow for high bandwidth closed-loop stage control.

The miniaturized sensor heads can be easily integrated into any system thus facilitating to measure as close as possible to the point of interest. This unique combination enables ever higher accuracy and quality in advanced display manufacturing applications.