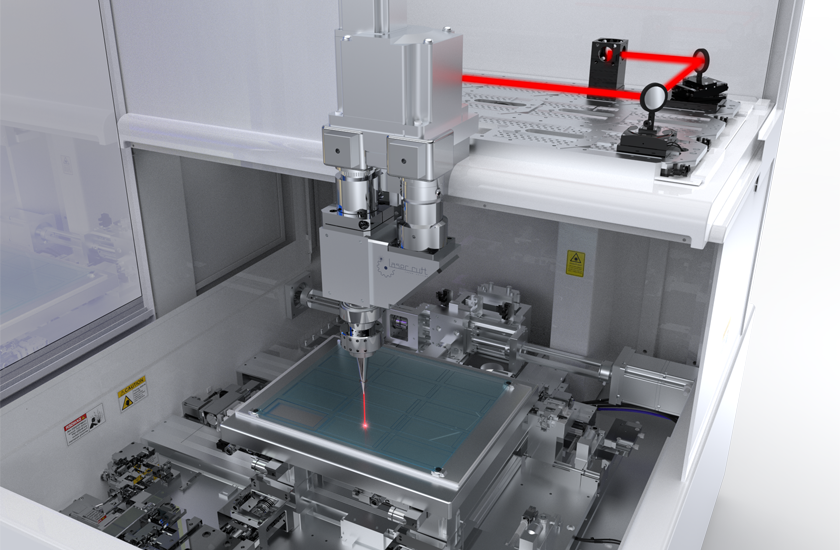

Beam Steering for High Power Laser Cutting

maximum precision for display manufacturing applications

Display manufacturing imposes highest demands on the cutting process of hard glasses and OLED screens. To achieve the required throughput and precision, high power laser cutting is the most suitable technology to process such complex materials. Even smallest production defects are critical: Not only because the used raw materials (as e.g. sapphire windows for camera protection) are expensive, but also because the workpieces may already include millions of sub-µm integrated circuits (as e.g. for OLED displays).

Therefore the laser beam must hit the workpiece with highest repeatability. This can only be ensured by a highly precise beam steering system, guiding the light from the laser source to the cutting head. To prevent misalignments - caused by e.g. thermal expansion - such systems require ultra stable positioning stages to ensure milli-degree precision in optics alignment.

attocube's solution

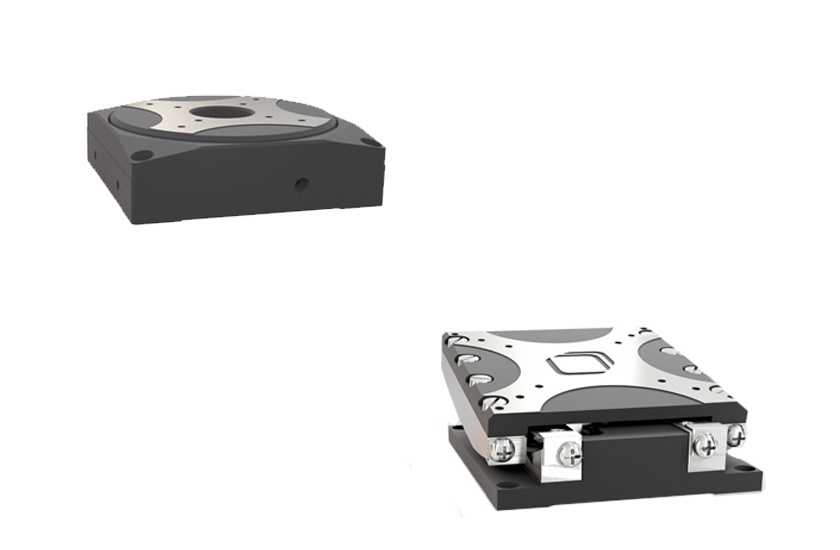

attocube goniometers and rotation stages are the perfect choice for high precision angular positioning. While the goniometers offer highest precision in the µ° range over a limited travel range, the rotators offer endless 360° motion.

On top, the self-locking piezo slip-stick drive ensures highest stability, while the modular design allows for flexible stacking of positioners to multi degree of freedom motion solutions.

Nanopositioners

Rotator: ECR5050hs

- 1 m° precision

- self-locking piezo slip-stick drive

- 360° endless travel

Rotator: ECG5050

- µ° precision

- self-locking piezo slip-stick drive

- 10° angular range