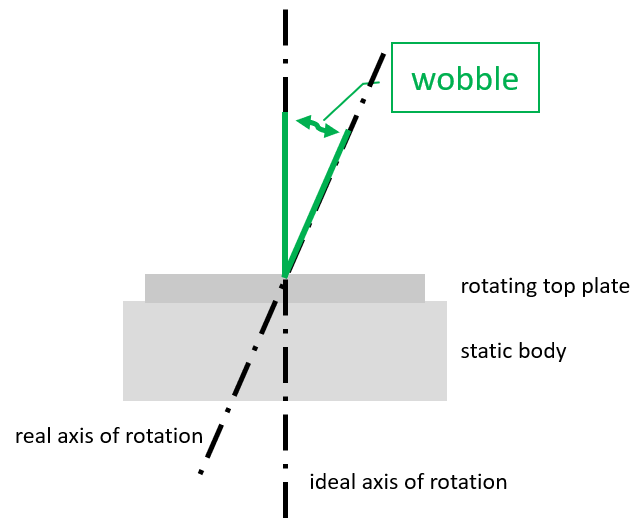

Wobble

Wobble is the position-dependent angular misalignment of the real axis of rotation relative to its ideal axis. Wobble is often cyclic in nature and is caused by the imperfect nature of mechanical components. It is defined for one full rotation (360°) and does not include any static offset of the rotating axis to an interface or mounting plate.

Holding torque

This is the torque that a rotary positioner (rotators and goniometers) inherently appliesmaintaining its static position around the rotation axis specified, even in the absence of anexternal force or respectively also when powered down. The self-locking mechanism is amain advantage of piezo slip stick inertia drives. In general, the holding torque is higher thanthe dynamic torque of a positioner. The holding torque is sometimes referred to as the statictorque.

Holding force

This is the force that a positioner inherently applies maintaining its static position along itsaxis, even in the absence of an external force or respectively also when powered down. Theself-locking mechanism is a main advantage of piezo slip stick inertia drives. In general, theholding force is higher than the dynamic force of a positioner. The holding force is sometimesreferred to as the static force.

Dynamic torque

This is the torque generated by a rotary positioner (rotators and goniometers) during itsmovement around the rotation axis specified. For positioners that rotate masses againstgravity or against external inertia, this property is sometimes referred to as lifting or pushingcapability. Please note that the moment of inertia that can be induced by a non-centeredload on the positioner has to be considered as a significant factor when accelerating withpositioners.

Dynamic force

This is the force generated by a positioner during its movement along its axis. It is the forcethat is required to overcome friction and inertia, and to accelerate the device. For positionersthat move masses against gravity or against external forces, this property is sometimesreferred to as lifting or pushing capability.

Maximum load

Maximum normal load refers to the maximum amount of weight or force appliedperpendicularly to the center of the mounting surface that a positioner can bear withoutdamaging its structure. The positioner needs to be mounted in the intended orientation.Loads around the maximum may influence other specifications.

Noise

Noise is the standard deviation σ of all additionally captured random values made during any static or dynamic ongoing measurement at a specific bandwidth.

Stability

The stability is the change in bias over time.

Sensitivity

Quotient of the change in an indication of a measuring system and the corresponding change in a value of a quantity being measured.

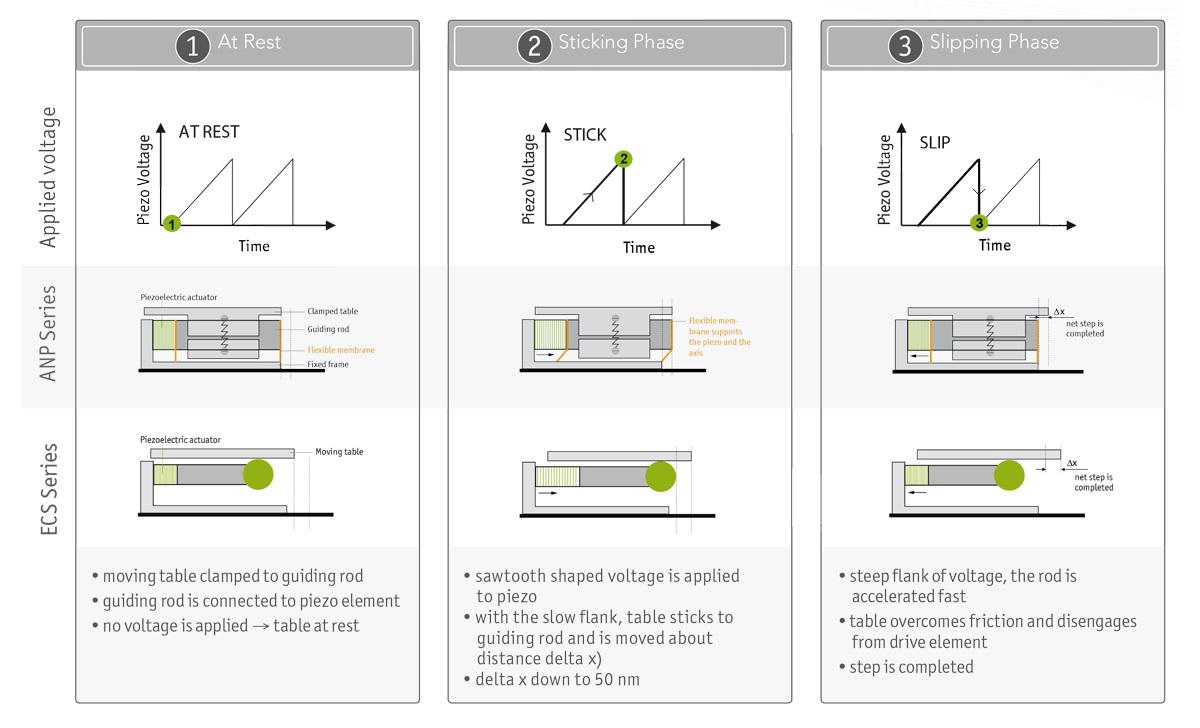

Slip-Stick Movement

Using the inertia of the positioner's top plate, the plate is moved by applying a saw-tooth voltage to a piezoelectric element which accelerates a guiding rod. The top plate is clamped to the guiding rod and only moved during the slow slope but stays at rest during the steep flank.

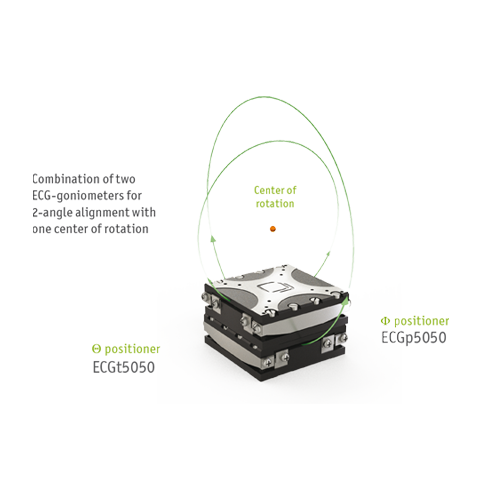

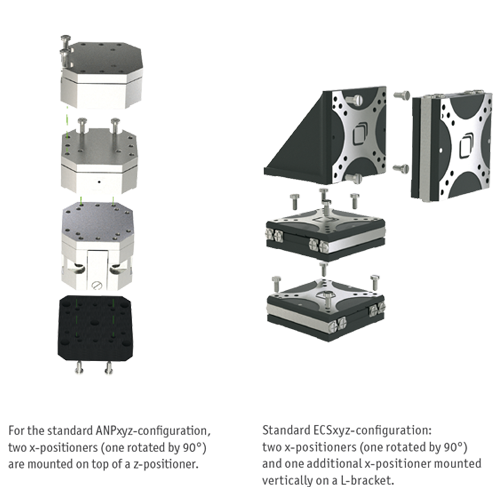

Combining Goniometers

Each size of goniometer is available in two versions which are usually used as a pair for theta (θ) and phi (φ) motion. The θ positioner mounted on top of the φ positioner forms a tip-tilt stage with a common center of rotation. Mounting is directly done with two or four screws.

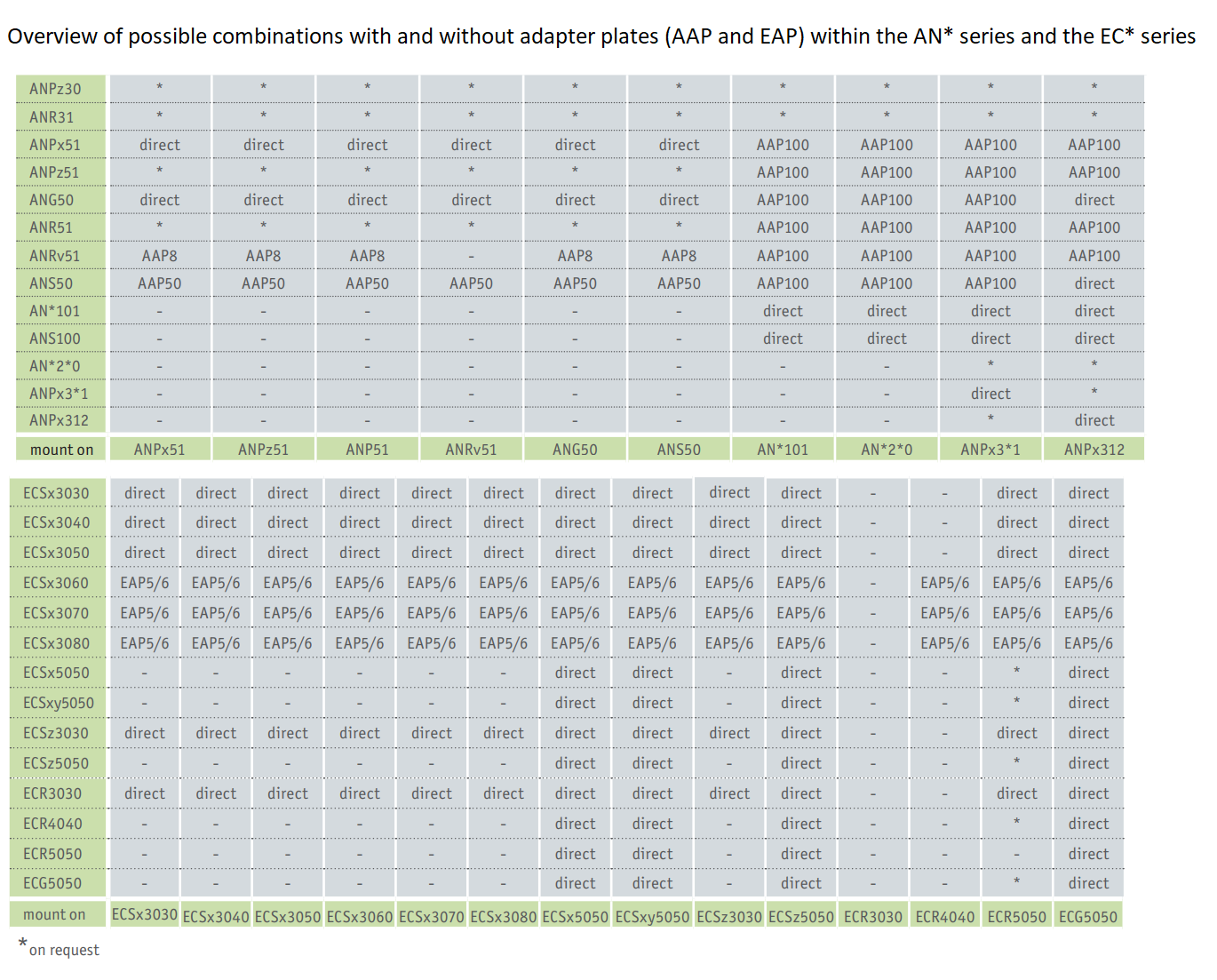

Cross Mounting Rules

Following general rules apply for building multi-dimensional setups:

- A positioner with a lower number should not be used to support one with a larger number, e.g. an ANPx51 should not carry an ANPz101.

- Cross-mounting between two differently sized models (e.g. a 51 series positioner on top of a 101 positioner) may necessitate an adapter plate (http://www.attocube.com/attomotion/accessories/adapter-plates-aap/ )

- All bearing-based positioners (ANPx3*1 series) can be mounted on a L-bracket which enables vertical positioning.

Merge Nanopositioning Stages to Multidimensional Systems

The modular concept of attocube positioners in combination with a consequent use of similar mounting patterns enables the assembly of multi-axis positioning units composed of several different types of nanopositioning stages. By merging several positioning units with distinct travel ranges and motion options, motor assemblies with up to six degrees of freedom can be built.

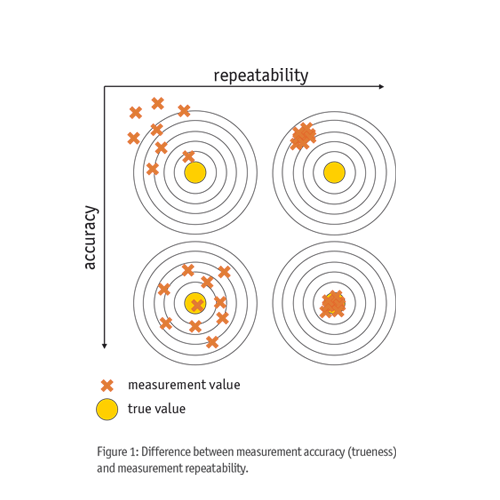

Precision

The precision is the standard deviation σ of a measurement. Its value is strongly related to the system’s noise level, its repeatability and – over duration – its stability.

Accuracy

Accuracy is the deviation of a device's measured displacement value compared to the true displacement of the target. Accuracy is defined as a percentage of the measured range.

Resolution

The measurement resolution is the smallest increment of displacement that the sensor can show.

Optoelectronic Encoder (/NUM, /NUM+)

The usage of a glass grating and the interpretation of the generated Moiré pattern characterizes the working principle of the /NUM and /NUM+ encoder. The measurement refers to the relative sample position with a position resolution of 1 nm and a repeatability of typically 50 nm for most linear stepping positioners. An absolute position information is also available via a reference mark. The /NUM+ features a reduced thermal dissipation of only 50 mW making it especially suited for /HV and /UHV positioners. The /NUM and /NUM+ encoders are available for our ECS series positioners.

Resistive Encoder (/RES, /RES+)

A resistive encoder (/RES) is used for our nanopositioners of the ANP series. The working principle of this encoder type is based on a potentiometer. It is the method of choice for applications at cryogenic temperatures, ultra high vacuum and highest magnetic fields. The /RES encoder measurement refers to the absolute sample position, for most linear steppers a repeatability of 1 µm is achieved. For ultra low temperatures (T < 1 K) a special /RES+ sensor is available which is included in all our /ULT models.

Encoder

Most of attocube positioners are available with optional encoders for closed loop control. The encoder allows to read back the actual position, while a feedback loop integrated into the corresponding electronics is used to minimize the difference between target position and actual position. Setpoints can either be defined in a software interface (ANC350, AMC100) or on the front panel of the closed loop electronics (ANC350).

Closed Loop Positioning

Positioners with an integrated encoder (/RES, /RES+ or /NUM, /NUM+) can be used for closed loop position control. A feedback loop integrated into the control electronics minimizes the difference between target position and actual position. Setpoints can either be defined in a software interface or on the front panel of the electronics (see electronics chapter).

Open Loop Positioning

The positioner is simply driven forward or backward, without an encoder reading the actual position.

Magnetic Field

attocube positioners of the ANP series (i.e. ANP, ANR, ANG and ANS) are built of completely non-magnetic materials such as titanium and ceramics. They can therefore be used in environments sensitive to magnetic materials, close to electron or other charged particle beams. They are especially dedicated for the use in high magnetic fields (currently maximum tested field: 35 T).

Ultra-High Vacuum (/UHV)

The ultra-high vacuum range is specified down to 5 ⋅ 10-11 mbar for most positioners. A few rotators and goniometers use UHV compatible grease. Due to the increased outgassing of these types at elevated temperatures, we specify them for 1 ⋅ 10-9 mbar as a precaution (noted in specification sheets). All UHV positioners can be baked out up to 150 °C.

High Vacuum (/HV)

The high vacuum range is specified down to 1 ⋅ 10-8 mbar.

Room Temperature (/RT)

/RT positioners are manufactured for use at ambient conditions (room temperature, dry atmosphere, ambient pressure).

Temperature

attocube has different positioner models for various temperature needs. All open loop positioners can be used in a temperature range of 0 °C to 100 °C in a non-condensing environment. For temperatures lower than this range, special versions (/LT, /ULT) are available. Due to the intrinsic nature of the semiconductors used in our precise optoelectronic encoder the /NUM sensor readout will only work up to a temperature of 50 °C (55 °C for NUM+). All UHV positioners can be baked out up to 150 °C.

Stepping Positioners

Stepping positioners are suitable for travel ranges in the mm range. They are driven via slip-stick principle (sawtooth voltage with an amplitude up to 70 V at LT).

Scanners

Scanners are suitable for travel ranges in µm range and their motion is continuous. The scanners are recognizable by the name „ANS“.