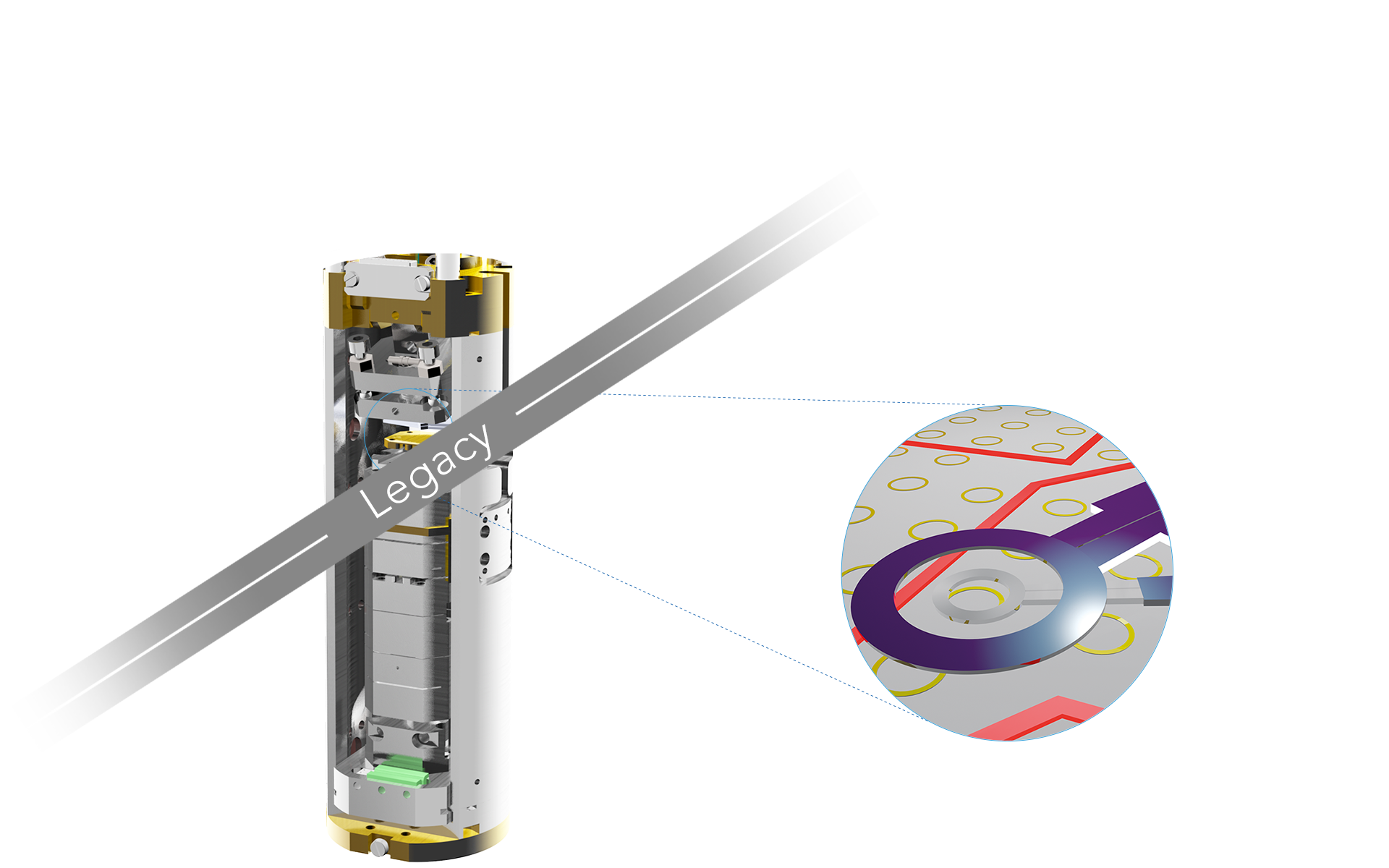

attoLIQUID1000

liquid helium based superconducting magnet systems

The attoLIQUID1000 is a liquid helium cryostat with a base temperature of 4.2 K, and with optional superconducting magnets. It is designed to host confocal & scanning probe microscopes, which are cooled by a Helium exchange gas atmosphere. The system includes all necessary components needed for the operation such as the renowned attoDAMP anti-vibration cabinet with acoustic damping, dual channel temperature controller, liquid helium level meter and probe, transfer line and all necessary vacuum fittings.

Manufacturing ended on January 31, 2023. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com

→ The official and recommended successor model of this product is the attoDRY1000.

attoLIQUID2000

liquid helium based cryostats for variable temperature operation

The attoLIQUID2000 is a liquid helium cryostat with variable temperature insert and temperature range from 1.8 .. 300 K, and with optional superconducting magnets. It is designed to host confocal & scanning probe microscopes, which are cooled by a Helium exchange gas atmosphere. The system includes all necessary components needed for the operation such as the renowned attoDAMP anti-vibration cabinet with acoustic damping, a suitable rotary pump for the VTI, a dual channel temperature controller, a liquid helium level meter and probe, a transfer line and all necessary vacuum fittings.

Manufacturing ended on February 2, 2022. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com

→ The official and recommended successor model of this product is the attoDRY2100.

attoRAMAN

low temperature micro-Raman spectroscopy system

attoRAMAN is a free-beam based confocal Raman microscope for use at low temperatures and in high magnetic fields, featuring hyperspectral imaging capability. It includes WITec Raman controller, ultra-high throughput spectrometer and powerful software suite. Over the years its application range became limited because of not being suited for detection of low-wavenumber Raman peaks, nor for polarization control.

Manufacturing ended on July 19, 2021. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com

→ The official and recommended successor model of this product is the cryoRaman

ANC350

multi-functional piezo controller for driving attocube's closed loop positioners

The ANC350 is a multi-functional piezo controller which meets the highly demanding dynamic performance and accuracy requirements of multi-axis nanopositioning setups. Dedicated controller models for driving either positioners with resistive encoders (ANC350/RES) or positioners with optoelectronic encoders (ANC350/NUM) are available in a three-axes version. Open loop positioners can be controlled in closed loop mode in combination with the ANC350/FPS and attocube’s FPS1010, FPS3010, FPS3010-19" setups.

Manufacturing of the ANC350/NUM and ANC350/FPS ended on April 1, 2019. Manufacturing of the ANC350/RES ended on April 1, 2021. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com

→ The official and recommended alternative for this product is the AMC300.

attoCFM II

fiber-based confocal microscope in reflection mode

attoCFM II is a fiber-based confocal microscope for use at low temperatures and in high magnetic fields in reflection mode. Based on a single-mode fiber and a fiber-based objective, it is designed for extended measurement periods of several weeks. Its application range is however limited by the wavelength range of single-mode fibers.

Manufacturing ended on April 2, 2020. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com

→ The official and recommended alternative for this product is attoCFM I.

attoSHPM

scanning Hall probe microscope

attoSHPM is a compact scanning Hall probe microscope designed for operation at low temperatures and high magnetic fields. It enables non-invasive measurements of local magnetic stray fields with lateral resolution of down to 250 nm. attoSHPM features coarse positioning of the sample over macroscopic distances with step size in the range of tens of nm, and an ultra-large scan range of up to 125 μm at 4 K.

Manufacturing ended on March 30, 2020. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com

→ The official and recommended alternative for this product is attoAFM I with MFM upgrade.

attoCFM III

fiber-based confocal microscope for transmission and reflection

attoCFM III is a confocal microscope with two fiber-based objectives for use at low temperatures and in high magnetic fields in transmission and reflection mode, each with its own detector. The two fiber-based objectives are independent, hence can feature single-mode fibers of different wavelengths. High stability of attoCFM III makes it suitable for spectroscopic measurements over extended periods of time.

Manufacturing ended on March 19, 2020. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com

→ The official and recommended alternative for this product is attoCFM IV.

sSQUID

quantitative microscale magnetic imaging

sSQUID is a microscope for quantitative measurements of weak local magnetic fields on the microscale. The probe is a SQUID scanned several hundreds of nm above the sample surface, and features ultra-high sensitivity of down to nT range. sSQUID can enable large temperature gradient of up to 100 K between the probe and the sample. Application range of sSQUID is limited by lateral resolution of > 1 µm, as well as by the lack of commercially available SQUID sensors.

Manufacturing ended on February 6, 2020. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com

→ The official and recommended alternative for this product is attoAFM I with MFM upgrade

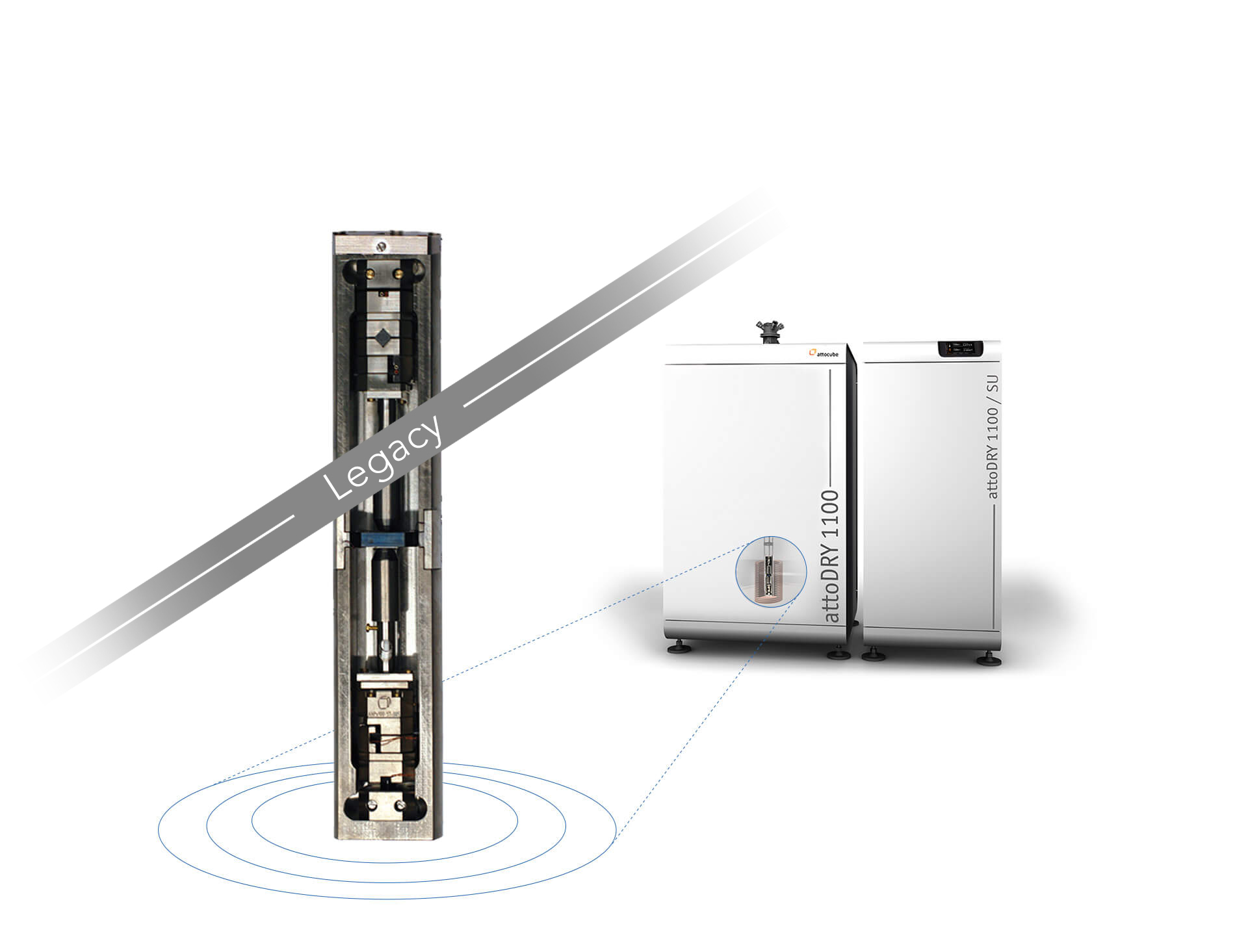

FPS3010

table-top displacement sensing

The FPS3010 is an ultra-precise interferometric displacement measurement and analysis system, equipped with three fiber-based sensor heads. It combines attocube’s superior interferometer technology with advanced software automation facilitating the interpretation of complex measurement data. Real-time serial-word and incremental interfaces allow the connection to other electronics and host controllers.

Manufacturing ended on September 16, 2019. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com

→ The official and recommended successor model of this product is the IDS3010.

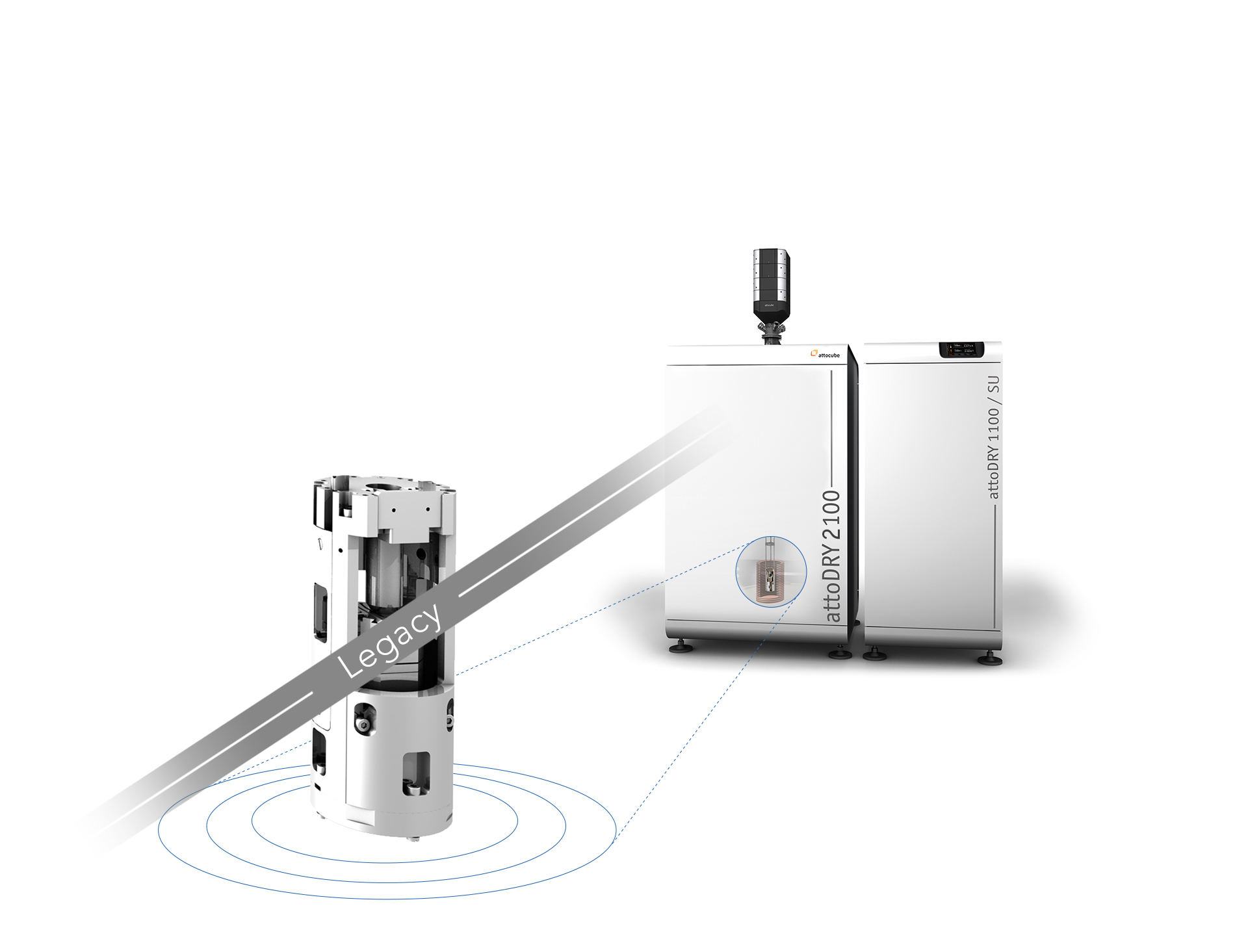

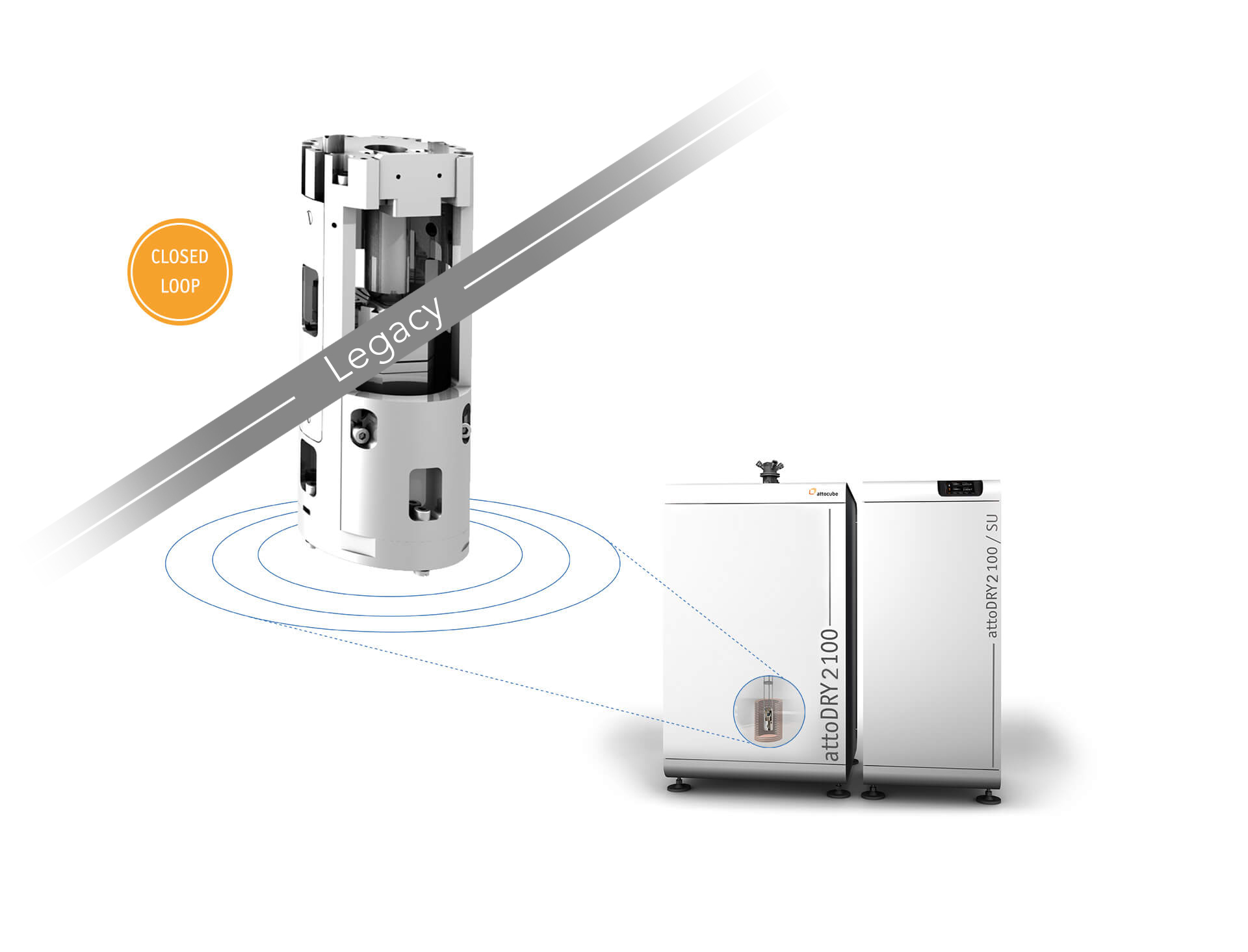

attoDRY1100

automated top-loading cryostat with superconducting magnet

The toploading attoDRY1100 is a closed-cycle low temperature measurement platform with a fully automated gas handling system and touchscreen control. It was specifically designed to provide an ultra-low vibration measurement platform for cryogenic confocal & scanning probe experiments without the need for liquid helium.

Manufacturing ended on May 10, 2019. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com

→ The official and recommended successor model of this product is the attoDRY2100.

attoLIQUID3000

liquid helium based Helium-3 cryostats with superconducting magnet

The attoLIQUID3000 is a liquid helium based cryostat with a 3He-insert for operation at temperatures from < 350 mK to 300 K, and with optional superconducting magnets. It is designed to host sensitive scanning probe microscope modules mounted on the 3He stage, and operated in cryogenic vacuum. All necessary components needed for a convenient operation are included, such as the renowned attoDAMP anti-vibration cabinet with acoustic damping, a suitable pump for the 1 K pot, a multi-channel temperature controller, a liquid helium level meter and probe, a transfer line and all necessary vacuum fittings.

Manufacturing ended on March 31, 2019. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com

→ The official and recommended successor model of this product are our customized mK microscopy solutions.

ECC100

three axes piezo motion controller for driving attocube's EC* series positioners

The three axes controller ECC100 is driving and controlling all EC* series positioners in open and closed loop mode. The ECC100 can be controlled through USB, input/output triggers, or Ethernet (optional) and is delivered with Windows based Software, DLL, LabViewTM, and EPICS (optional) drivers set

Series production of the ECC100 ended on May 1, 2018. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com

→ The official and recommended successor model of this product is the AMC100

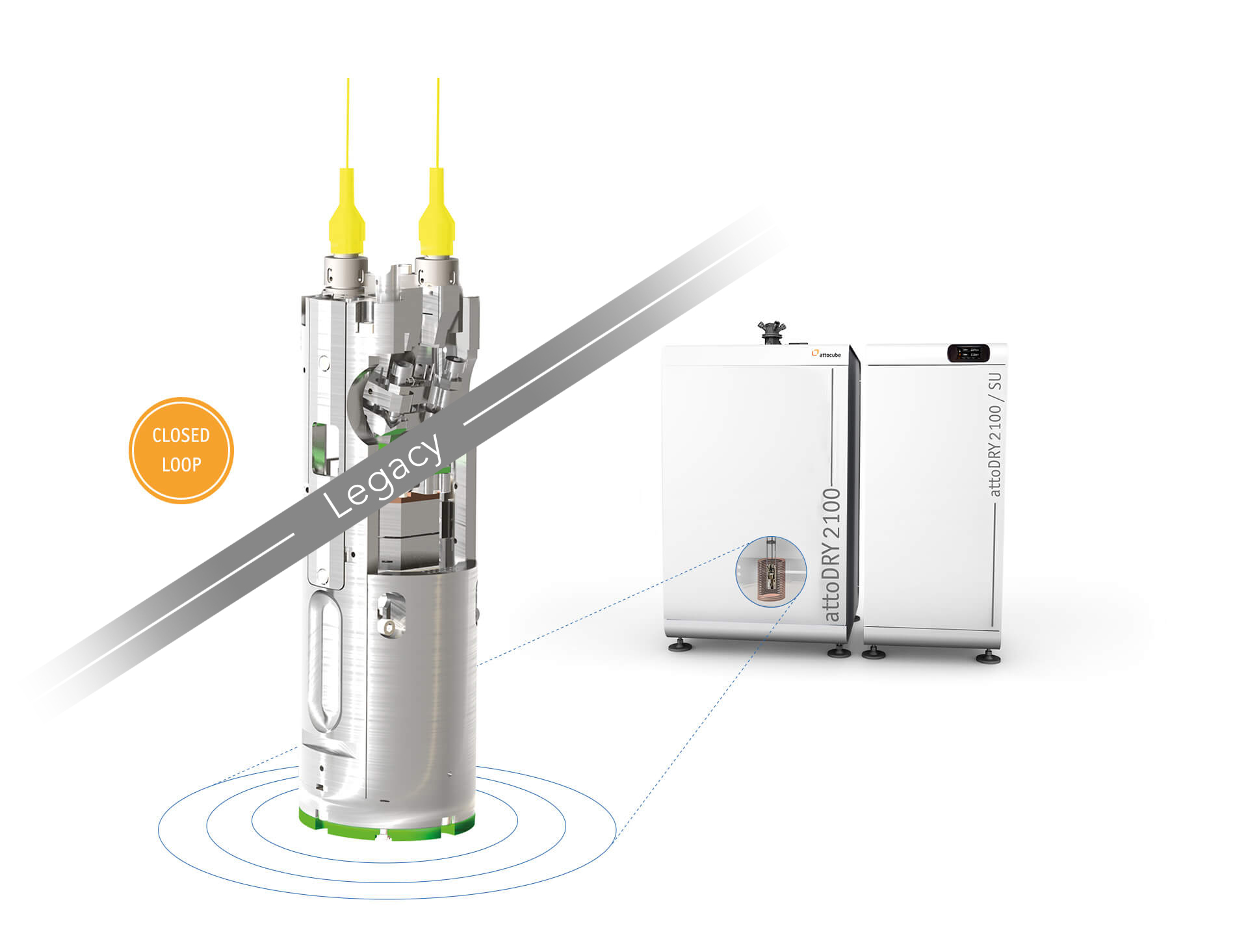

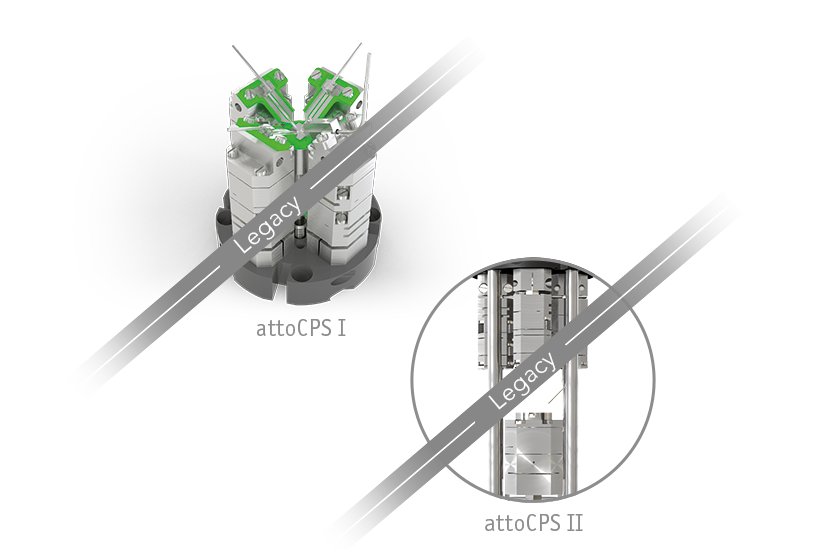

attoCPS

cryogenic electrical probe station for in-situ multi-device testing

attocube’s cryogenic probe stations are based on up to 4 electrical (or fiber) probes each mounted on independent sets of xyz nanopositioners, which allows for flexible in-situ multi-device testing at cryogenic temperatures and in high magnetic fields.

Manufacturing ended on January 1, 2017. According to our terms & conditions, our products are supported up to 5 years after their delivery. For more information contact support@attocube.com