attoDRY2200

automated toploading ultra-low vibrations cryostat for ultra-sensitive SPM measurements

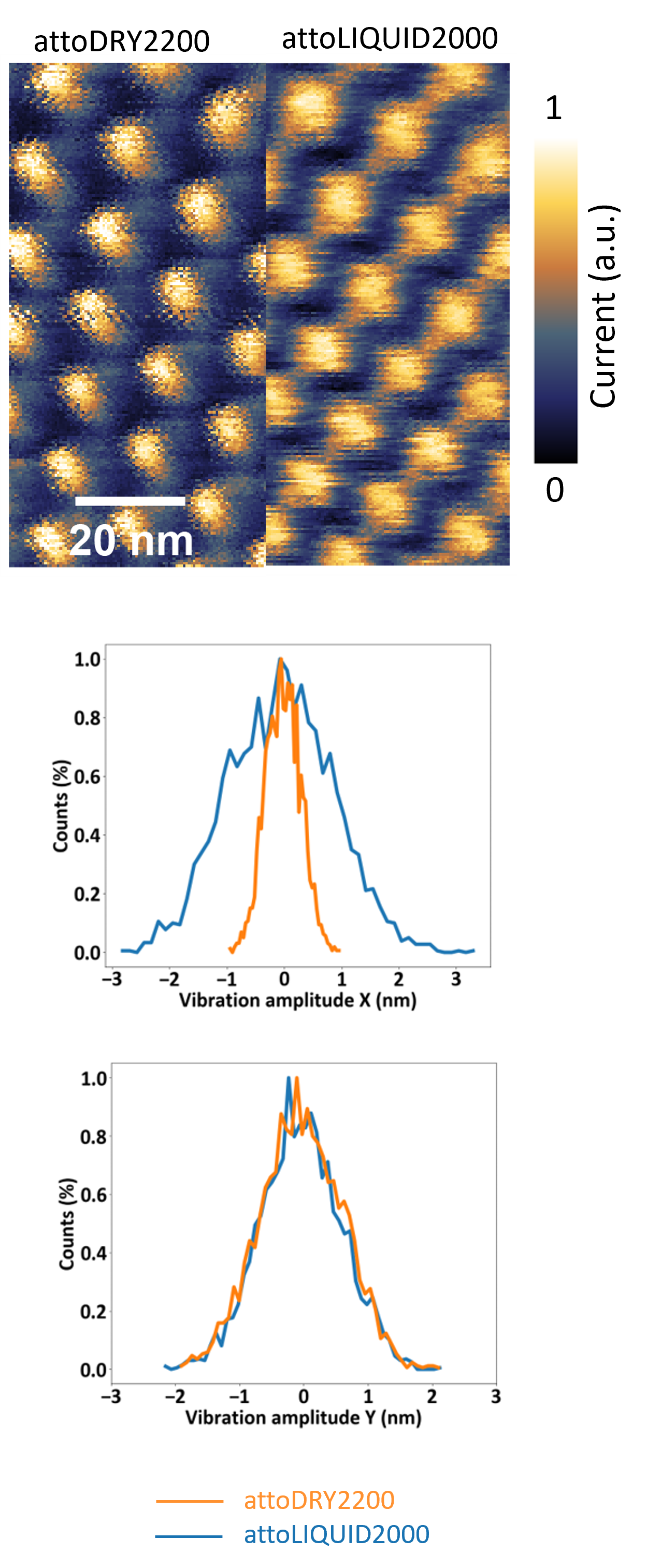

the new benchmark in ultra-low vibration

makes liquid cryostat obsolete even for the sensitive AFM measurements

automated control via eNSPIRE electronics

web-server, live plotting & logging, versatile API

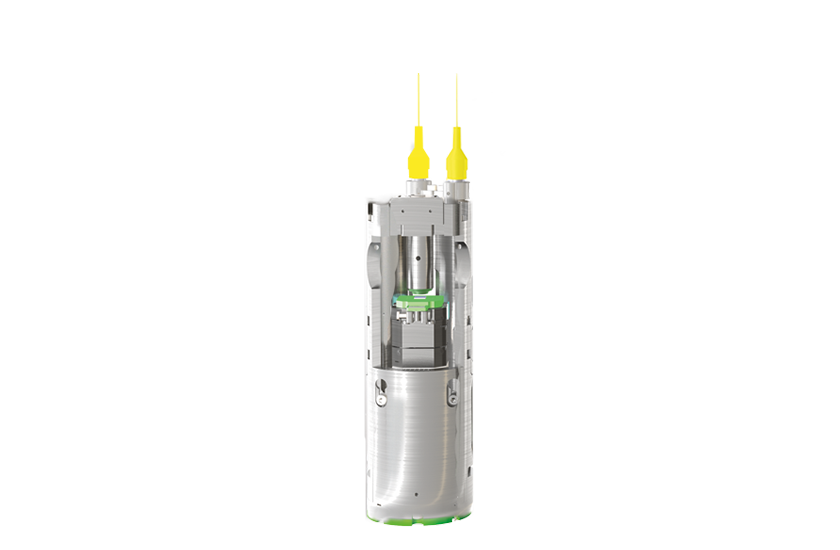

toploading probe with free-beam access in vector magnetic fields

versatile SPM platform for 2D materials research

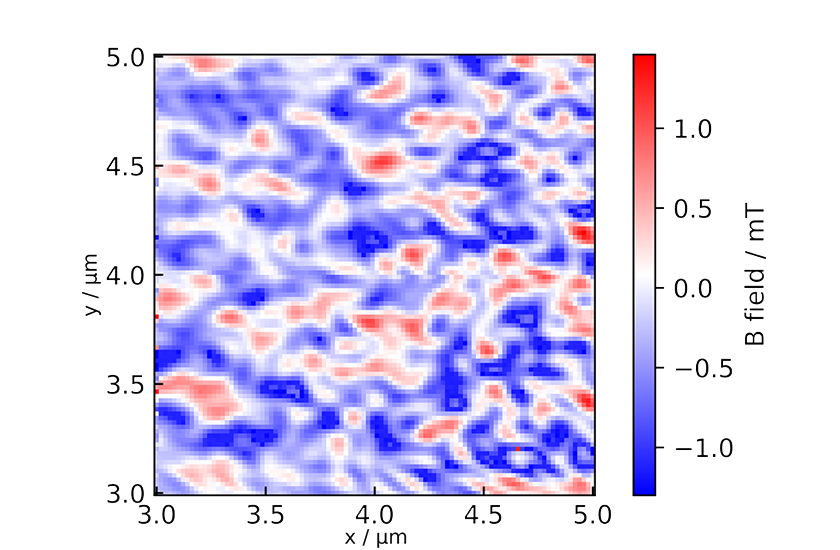

A broader adoption of groundbreaking technologies and material systems like quantum sensing (ODMR), 2D magnets, and skyrmions, requires closed-cycle cryostats to reach a whole new level of evolution in vibration stability and to enable nanometer lateral resolution, while at the same time still offering variable magnetic fields.

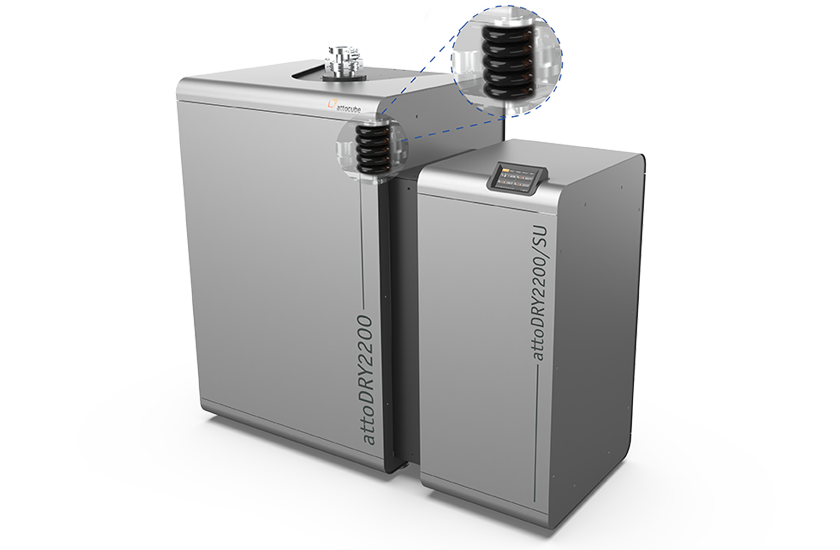

The closed-cycle cryostat attoDRY2200 is attocube’s answer to those demanding requirements and will make the mentioned technologies more accessible to a broader community. Equipped with a proprietary ultra-efficient vibration-damping system, a choice of vector magnets, and an automated, user-friendly, variable temperature control, this cryostat is the best choice to implement state-of-the-art SPM measurements.

The attoDRY2200 offers a fully automated cooldown from 300K to a base temperature of down to 1.65K – and everything in between. Complimented by an automatic magnetic field control, the superconducting vector magnets make the maximum magnetic field over the whole temperature range easily accessible.

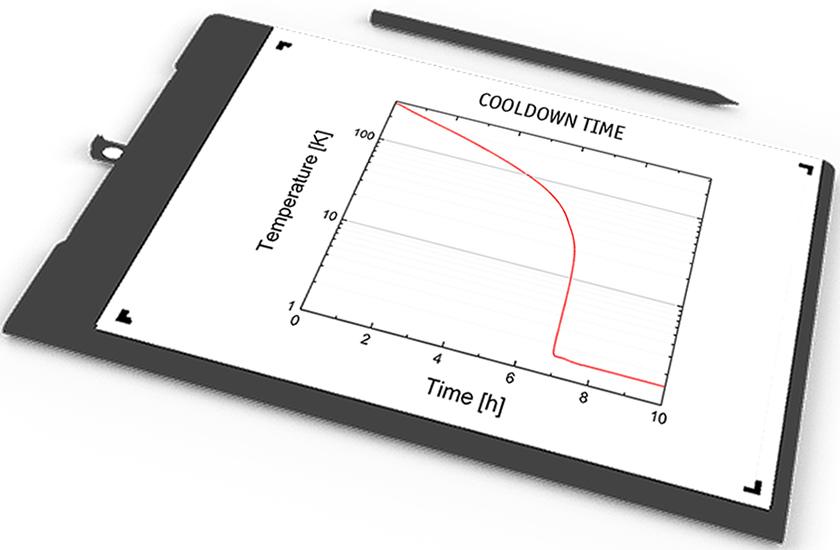

The unmatched cooling performance via exchange gas coupling provides an initial cooldown time of the complete system of around 15-20 hours, while the turn-around time during sample exchange is around 5-8 hours. The integrated touchscreen allows for conveniently setting the desired field (B) and temperature (T) without using a PC.

More elaborate measurement schemes such as programmable sweeps of B and T are easily possible via versatile application programming interfaces (APIs). The top-loading design enables a quick and easy sample exchange, while offering a generous sample space of 49.7 mm in diameter.

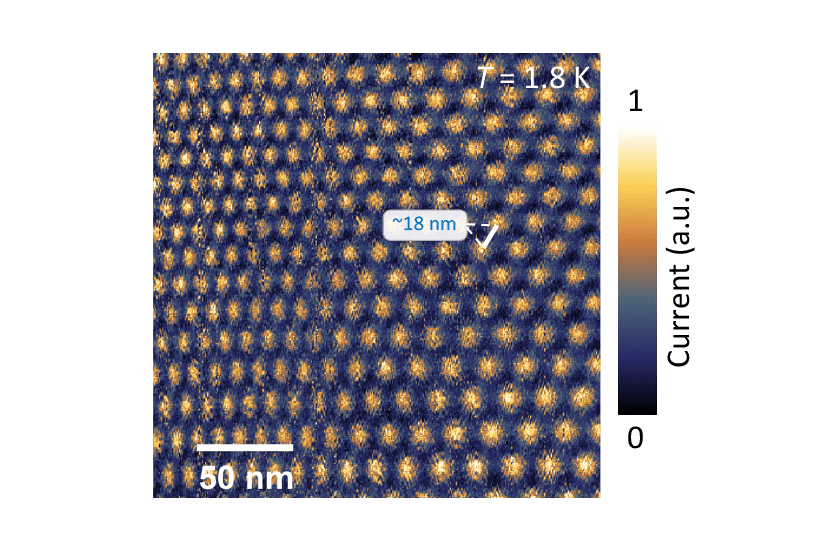

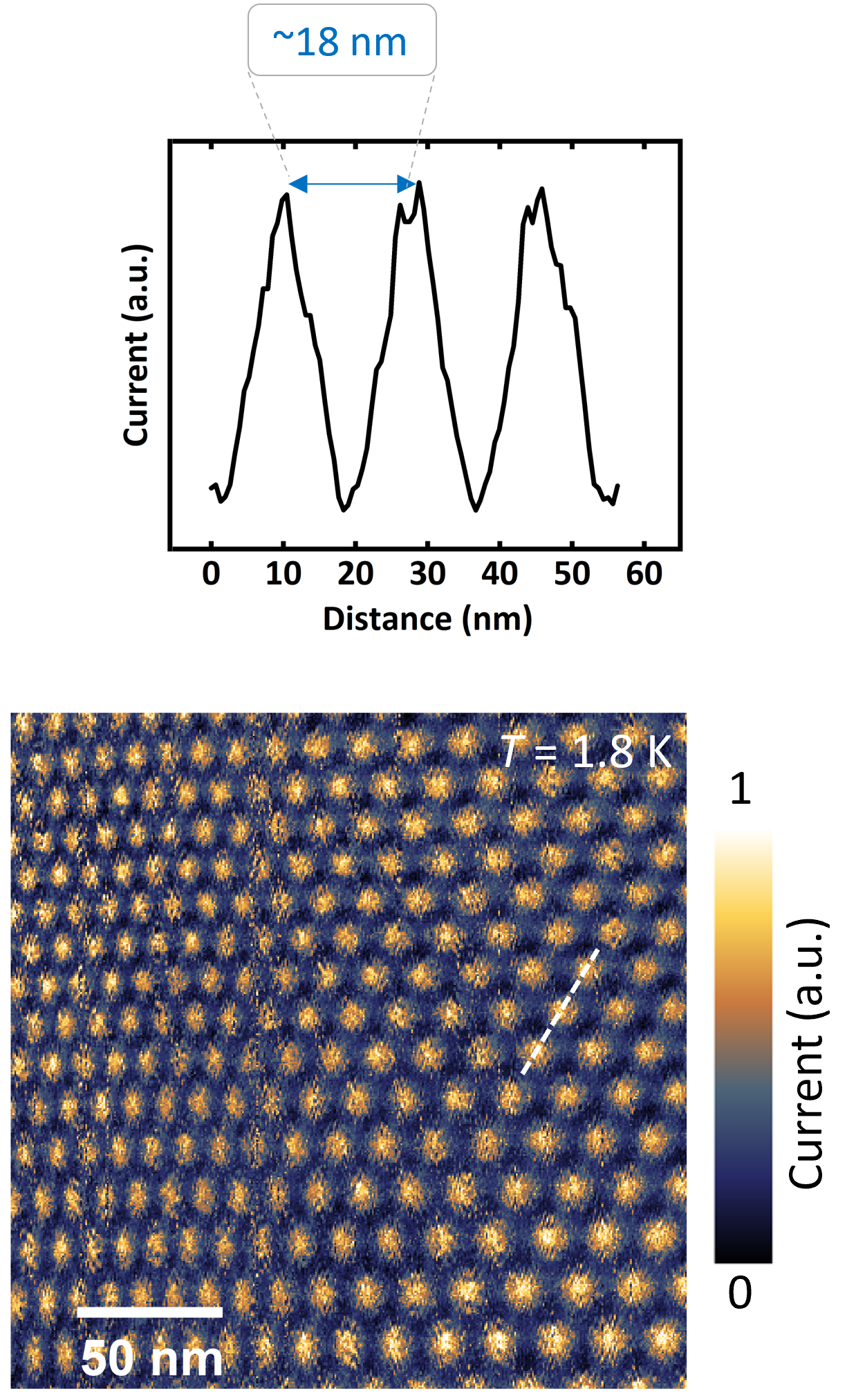

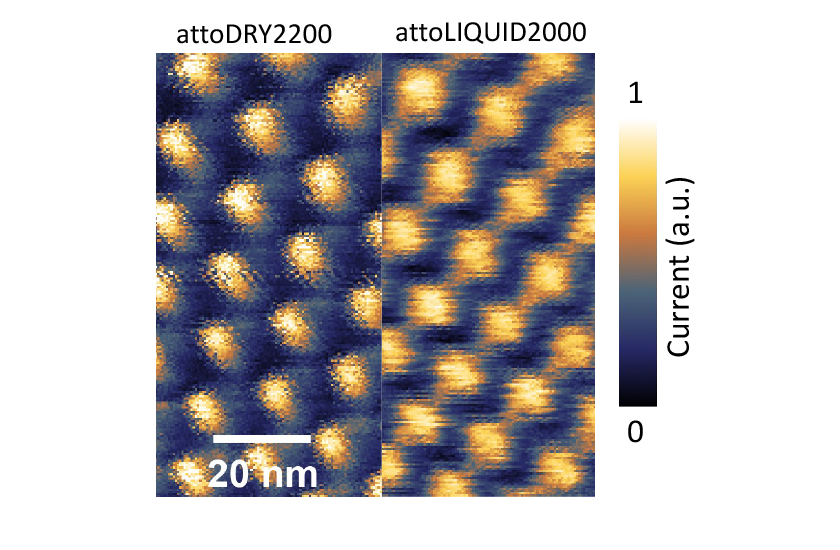

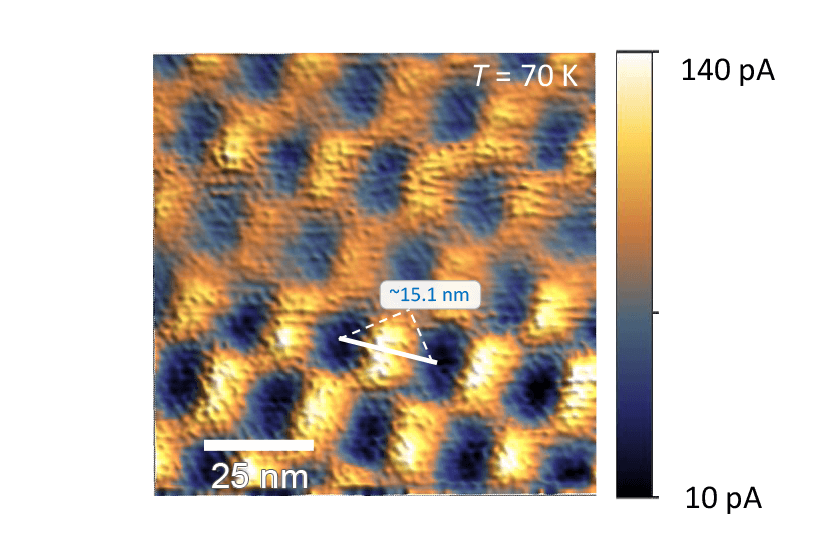

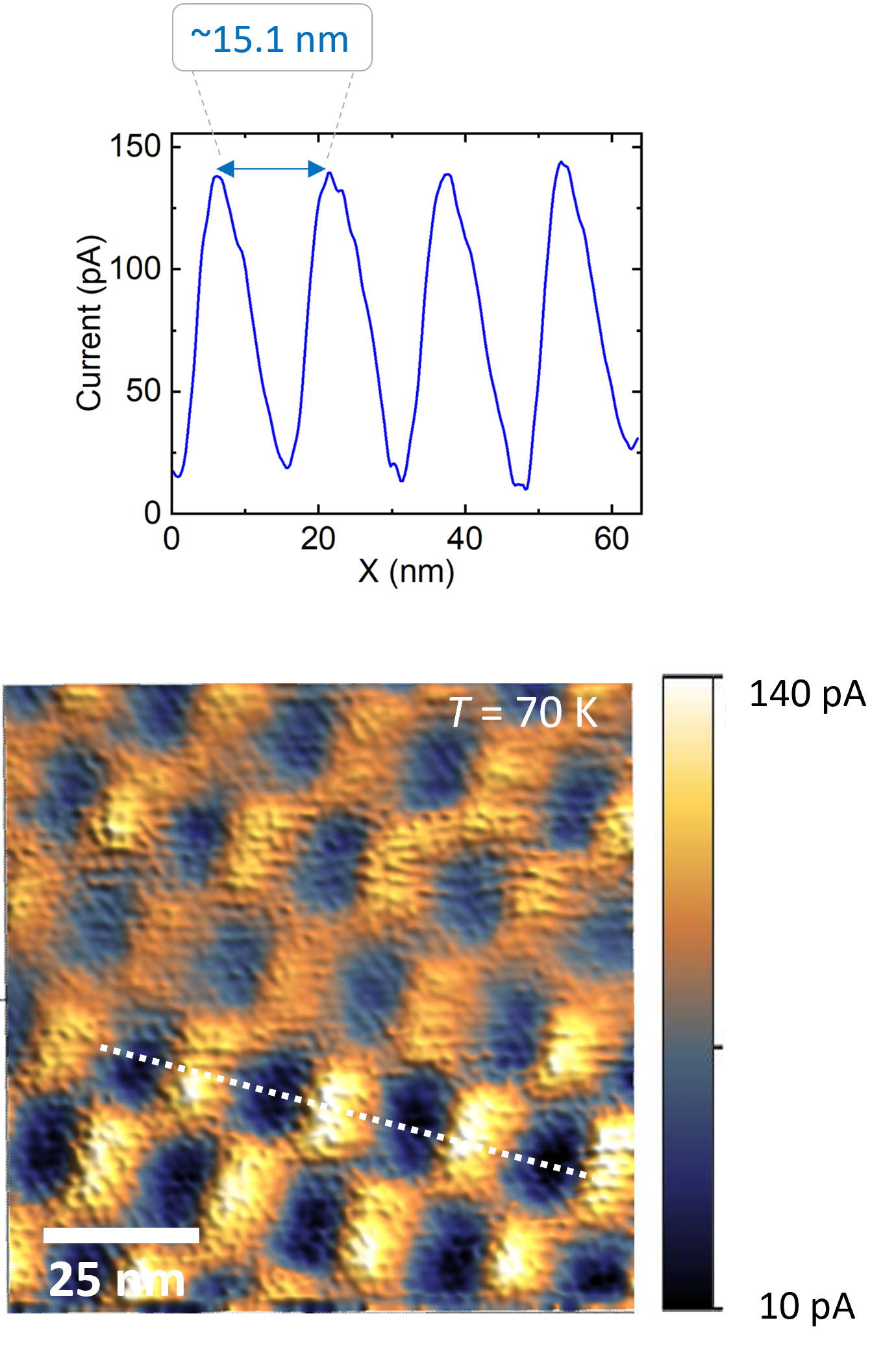

The closed-cycle cryostat attoDRY2200 constitutes a unique ultra-low vibration measurement platform for cryogenic scanning probe experiments without the need for liquid helium. By the additional damping system, the mechanical vibrations created by the pulse-tube coldhead are extremely efficiently decoupled from the sample space. Our internal application measurements have confirmed an extremely high lateral stability in our scanning probe microscopes. This allows for a lateral resolution in atomic force microscopy that matches or even outperforms the performance in previous liquid-helium-based variable-temperature magnet cryostats. The attoDRY2200 paves the way for ultra-sensitive SPM on hot topics such as 2D materials, domain walls, multiferroics or superconducting samples with nanostructures.

Selected Measurements

attoDRY2200 – the new benchmark for ultra-low vibration low-temperature SPM

Specifications

For a detailed definition of used terms and descriptions please visit our Closed-Cycle Cryostats Glossary

| General Specifications | |

|---|---|

| technology | ultra-low vibration, pulse-tube based closed-cycle cryostat, designed for scanning probe microscopy applications |

| sample environment | He exchange gas |

| sample space | 49.7 mm diameter probe bore fitting all attocube inserts |

| sample exchange | top loading system for quick access |

| usability | fully automated temp. and mag. field control via integrated touchscreen, web interface or LAN API |

| vibration & acoustic noise damping system | benchmark ultra-low vibration design |

| Performance Data | |

| temperature control | fully automated, including all pumps and valves, touchscreen & remote control via PC |

| temperature range | 1.8 .. 300 K (automated control) |

| base temperature | 1.65 .. 1.8 K (for standard inserts) |

| magnetic field control | via touchscreen, via remote control, via API |

| cool down time of sample | approx. 5 .. 8 h (depending on insert) |

| initial cool down time of system without insert (unattended) | 15 .. 20 h (system without magnet), 25 .. 30 h (incl. 9 T magnet) |

| Compressor | |

| power consumption | max. 9.0 kW, 7.2 kW steady state |

| cooling of compressor | water cooling (requires local infrastructure) |

| Size and Dimensions | |

| cryostat (width x depth x height) | 1450 x 793 x 1360 mm³ |

| required min. ceiling height | approx. 2.60 m (depending on magnet) |

| optional electronics rack (width x depth x height) | 640 x 640 x 1050 mm³ |

| weight | 420 .. 520 kg (depending on magnet) |

| Options and Upgrades | |

| superconducting magnet | solenoids: 9 T, vector magnets: 1/1/1 T, 5/1/1 T, 9/1/1 T |

| bipolar magnet power supply | included (with optional magnet) |

| temperature controller | included |

| pumping kit | turbomolecular pump with suitable backing pump for sample space preparation |

| Compatibility | |

| confocal microscopes | attoCFM I, attoCFM IV |

| atomic force microscopes | attoAFM I , AFM upgrade options (MFM, KPFM, PFM, conductive-tip AFM), attoAFM III |

| transport measurements | atto3DR |

Features

Dampers

next generation vibration damping optimized for sensitive LT-SPM