Measurement Explained

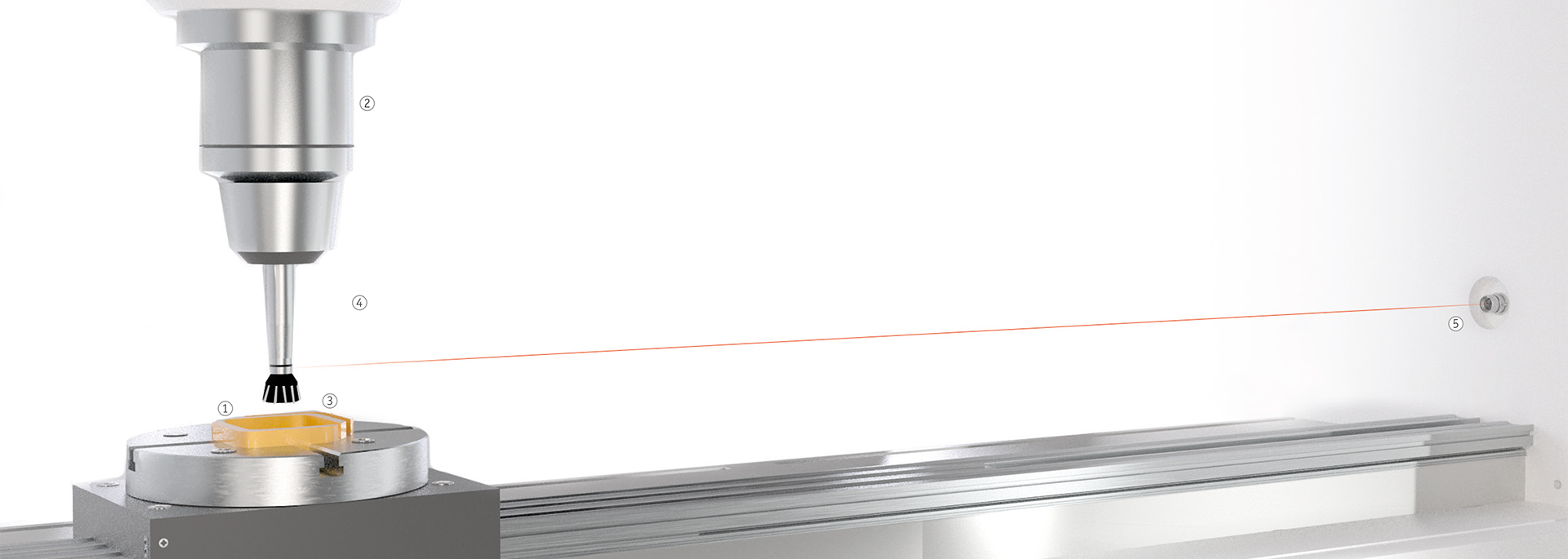

how to install and use the interferometer

For measuring displacements in a nanometer scale, the sensor system has to suit the application specific conditions. As each application has its own characteristics, it is important to adapt and install the sensor and sensor heads accordingly.

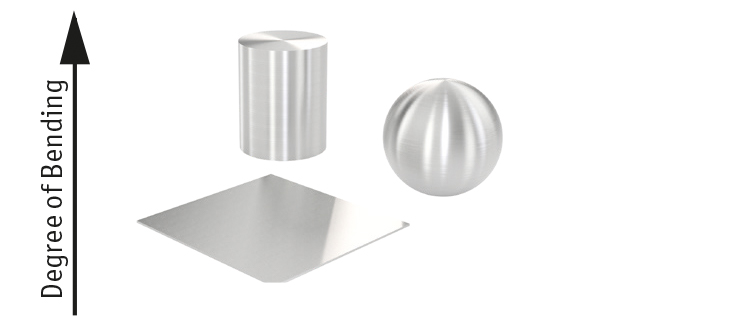

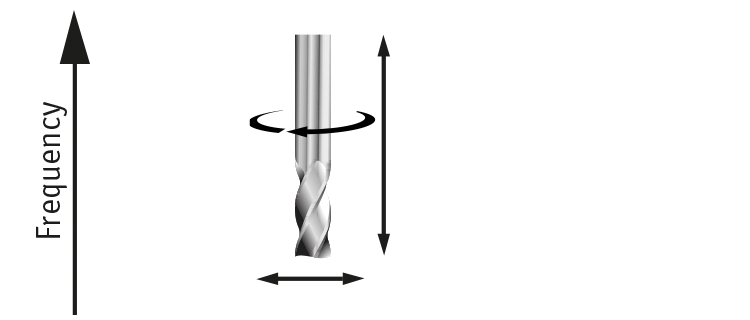

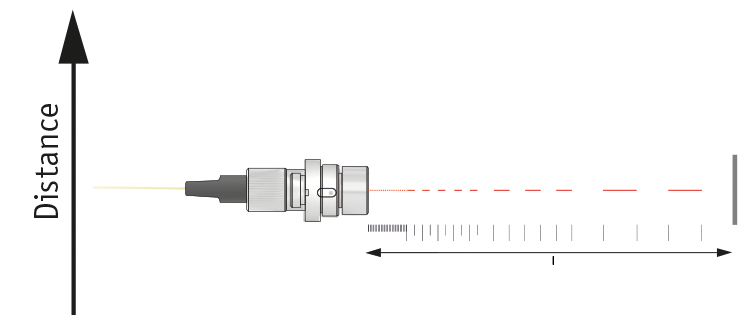

For each measurement set-up, the following details have to be taken in consideration: geometrical shape of target, type of motion, material/surface quality, environmental conditions, and working distance. Check the graphic below for further explanation.

|

|

|

|

|

|

|

|

|

|

How to select the appropriate sensor head?

In order to provide a sensor system adapted to the specific conditions of your application, our sales personnel supports you in finding the fitting standard sensor head or defines the criteria for a customized sensor head. They will also attend the installation and testing of your measurement setup.