Vibration Analysis & Compensation

interferometer for monitoring vibrations and differential movements

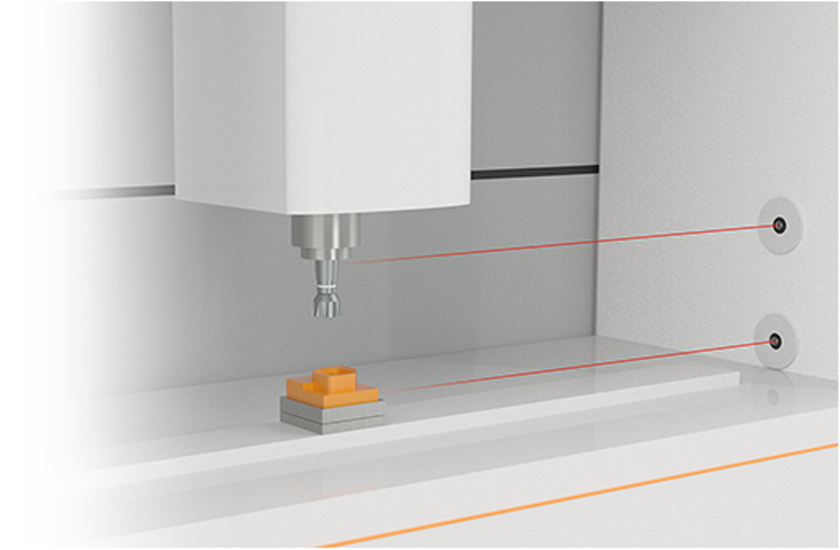

Manufacturers of high-speed machine tools are facing diverse challenges in handling vibrations and unintended movements from machine components as well as the workpieces. Not only does vibration limit the machine’s performance, if left uncorrected, it also creates wear and damages, lowering the life-time of expensive components.

Advanced and contactless vibration analysis could increase the reliability of the process by identifying the optimized parameter settings and predict maintenance. Unfortunately, limited spaces, ultra-high frequencies in different dimensions, and limited amplitudes in the nanometer range hinder the integration of conventional sensors.

attocube's solution

Thanks to the fiber-based design, the IDS3010 interferometer sensor is capable of monitoring high frequency vibrations in real-time under limited space conditions. By using multiple channels, even angular vibrations and relative velocities between different components can be detected – the basis for active vibration compensation.