Motion Tracking for Mechanical Load Tests of Gear Boxesand Drive Power-Trains

The components in drive engineering industries need to be tested for numerous mechanical characteristics, e.g. gear boxes need to be checked for long-term smoothness, synchronization, backlash, torsional stiffness, tribological behavior, and/or mechanical resilience. WITTENSTEIN alpha develops and produces mechanical and mechatronic servo drive systems for applications that require maximum precision. The testing facilities of WITTENSTEIN are fitted with vertical, linear motion gearbox test benches.

Since the integrated glass scale is limited in measurement accuracy and bandwidth, WITTENSTEIN uses attocube´s fiber-based interferometer IDS3010, which provides picometer resolution and up to 10 MHz real-time data output. Furthermore, the laser based measurement and the miniaturized components allow to measure as close as possible to the point of interest, without influencing the setups behavior. This enables test and development engineers to determine mechanical and tribological phenomena that could not be detected using conventional glass scales.

This measurement was realized with the Displacement Measuring Interferometer.

Deformation Detection of Satellite Flight Instruments

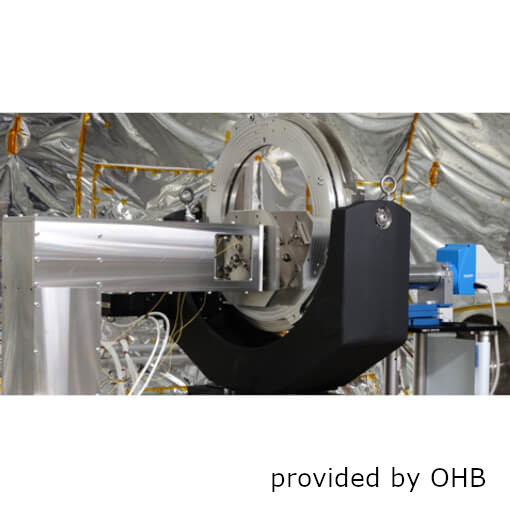

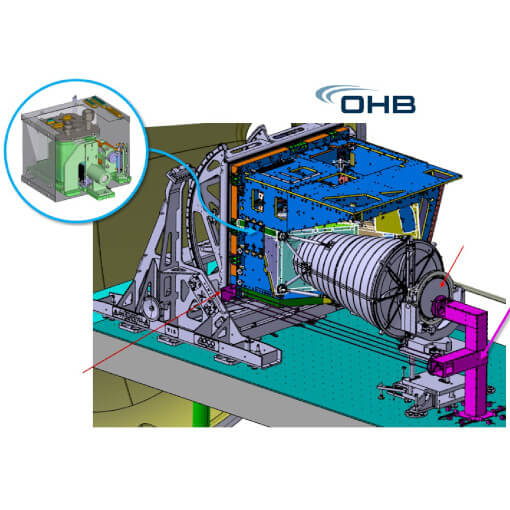

The space environment imposes extremely stringent design constrains on observation spacecrafts, especially in terms of thermo-elastic stability, leading to the use of advanced materials and thermal architectures. These constrains also translate into demanding validation processes including accurate characterizations and thermo-mechanical models correlations by means of ambient and high vacuum test campaigns.

OHB system AG used attocube’s interferometric displacement sensor, IDS3010, for an opto-thermo-mechanical model correlation test in high vacuum for the Meteosat Third Generation (MTG) Flexible Combined Imager instrument.

The test consisted in injecting controlled thermal fluxes in different zones of the instrument and monitor its subsequent optical elements relative displacements measured with a Shack-Hartmann sensor. With the precise measurement of the IDS3010 the stability of the relative position of a flat reference mirror and the IRS instrument was continuously monitored with an accuracy of less than 1 arcsecond during the whole duration of the test which lasted more than a week in vacuum in total.

This measurement was realized with the Displacement Measuring Interferometer.

Fast Calibration of Machine Tools based on the IDS3010

Researchers at the Chair of Production Metrology and Quality Management at the Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen University investigate the possibility of self-calibrating machine tools: a laser interferometer and other sensors will be integrated into a machine tool for automated online measurements of the axes' motion errors. This makes time-consuming manual calibrations redundant that require to interrupt the production process and to install and to demount the calibration equipment.

The researchers built a prototype for a single-axis setup that utilizes the IDS3010 for position tracking. Other sensors like a CMOS camera were used to detect pitch and yaw. The calibration results were compared to the results of a conventional calibration system: while the six motion errors (position, pitch, yaw, y-straightness, z-straightness) show a good agreement for both systems, the total time and costs where significantly lower using the IDS3010. The setup demonstrated a first prototype for a self-calibrating machine tool and shows that an automated procedure reduces machine downtimes, thus enhancing productivity by keeping the same level of accuracy.

This measurement was realized with the Displacement Measuring Interferometer.

Optical Interferometer in Quality Control of a Nanopositioner

We've combined two of our products to ensure the highest quality delivered to our customers: In this application note we show the implementation of the FPS3010 interferometer in the quality control process of our nano drives. The outstanding precision of the FPSensor will ensure that every positioner delivered fulfills the highest quality standards, whereas the easy & robust alignment of the sensor permits high throughput, and therefore reduced lead-time.

This measurement was realized with the Displacement Measuring Interferometer.

OEM Interferometers for motion tracking in coordinate measurement machines

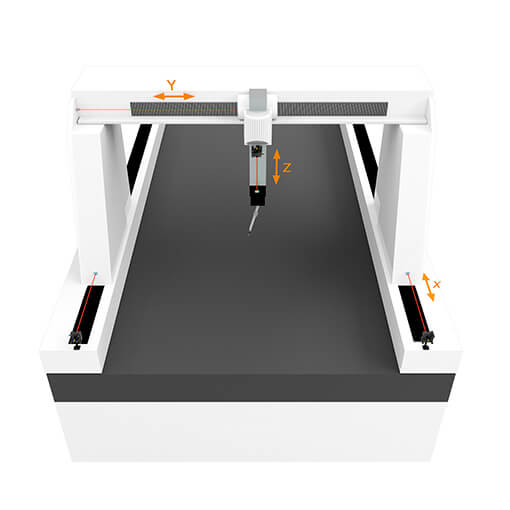

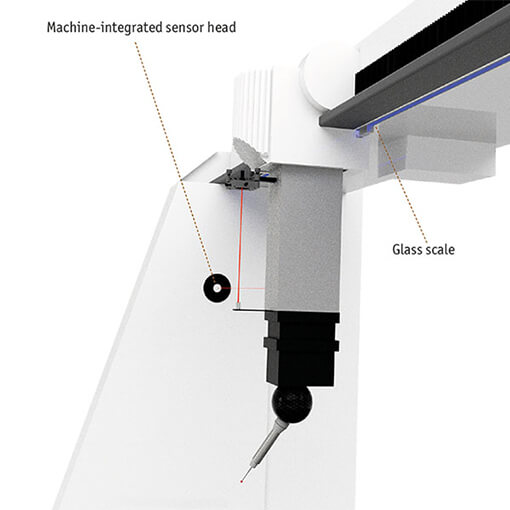

Coordinate measurement machines (CMM) have highest requirements towards precision. CMM determine geometrical dimensions of simple and complex products and components for quality control (e.g., measurements of manufacturing accuracy or tribological measurements). Those applications require an accuracy in a sub-micrometer range, while the calibration and the machine-integrated control need a higher level of accuracy.

The laser interferometers of attocube are solutions providing highest precision and large working distances at the same time - suiting the challenging requirements of CMM. While the IDS3010 allows to measure displacements of up to 5 meters, it simultaneously detects overshoots in the nanometer range. Furthermore, the compact design of the IDS3010 and the sensor heads fits machine-integrated applications.

Customers can choose:

- target velocity up to 2m/s

- direct beam or mirror deflection

- Workings distances of up to 5 meters with a constant precision in nanometer range

- In situ measurements on the touching probe without Abbe errors instead of mechanically transmitted position acquisition (e.g glass-scales)

- Compact interferometer unit for machine-integration

This measurement was realized with the Displacement Measuring Interferometer, and the .

Long distance and high-speed displacement measurements

Machine vibrations induce errors in parts manufacturing. The miniscule vibrations of a milling machine produce erratic motions of the workpiece with regards to the cutter and hence, may lead to contouring errors or a bad surface finish. Such defective parts create problems and can jeopardize the whole system’s assembly or safe operation. In the end, they may fail quality criterions such as the 6-σ standard. Get our latest application note & see how the FPS3010 can help to efficiently and precisely characterize vibrations, thus helping to succesfully eliminate these errors.

This measurement was realized with the Displacement Measuring Interferometer.

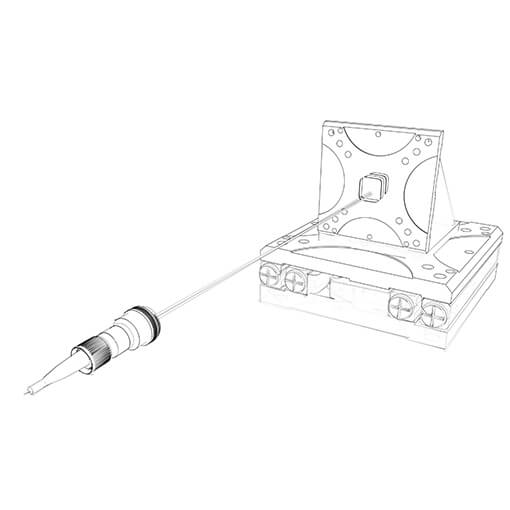

Position Capturing in Coordinate Measurement Machines

Cordinate measurement machines (CMM) measure more than just distances, they are capable of capturing a broad range of geometries: angles, profile of a surface, parallelism, symmetries, tolerances, circularity, and much more. For those applications, CMM provide an accuracy in a sub-micrometer range. To enable this level of accuracy, CMM need even more accurate sensors to be calibrated.

Since glass-scales do not measure the displacements of the touch probe itself, they cannot detect the actual overshoots and motion of the touch probe. Because of the contactless measurement technology, attocube’s IDS (Industrial Displacement Sensor) is capable of focusing on the touch probe directly and capturing the motions at the point of interest.

This measurement was realized with the Displacement Measuring Interferometer.

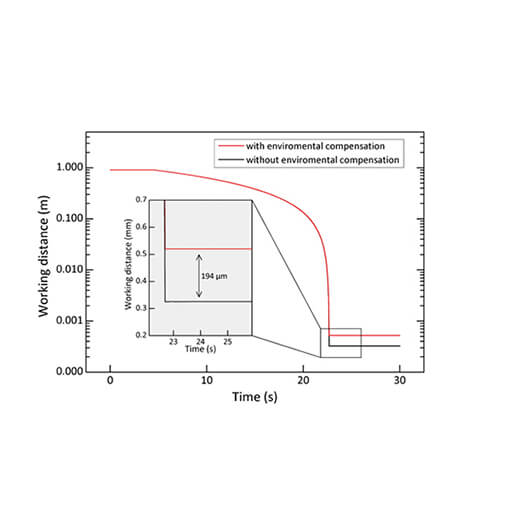

Environmental Compensation

Any interferometric device operated in environmental conditions is negatively influenced by index of refraction fluctuations, caused by air temperature, pressure, and humidity variation. The influence of these parameters is significant and can reach deviations in measurement of up to 500 ppm, equivalent to a deviation of 500 µm per meter.

To compensate these errors, attocube offers an environmental compensation unit (ECU) which precisely measures environmental parameters and determines the actual index of refraction n(t). This measurement allows to compensate environmental influences down to better 1 ppm and enables highly precise, accurate measurements in air.

(attocube application labs, 2017)

This measurement was realized with the Displacement Measuring Interferometer.