Displacement Sensing in Additive Manufacturing with attocube's Interferometer

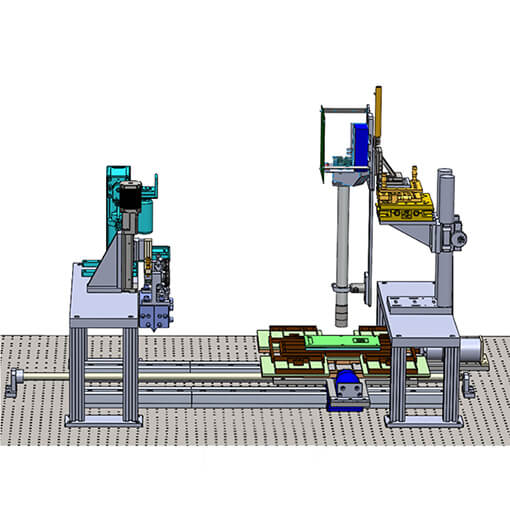

An innovative method for manufacturing integrated circuit package building blocks (e.g. microcontrollers) is the so-called micro-scale selective laser sintering (µ-SLS). Additive manufacturing is state-of-the art in many engineering applications requiring accuracy in the micrometer range. However, the production of integrated circuit packages are in dimensions on the order of a few micrometers and need smaller tolerances than conventional additive manufacturing methods can provide.

The University of Texas and the company NXP Semiconductors have developed a new 3D printer based on the µ-SLS technology for manufacturing integrated circuit packages. This system includes an air bearings linear guide rail for transporting the work piece between the sintering station and the slot die coating station. Since this guide rail has highest requirements on position accuracy, attocube's interferometer is used for position tracking.

This measurement was realized with the Displacement Measuring Interferometer, and the .

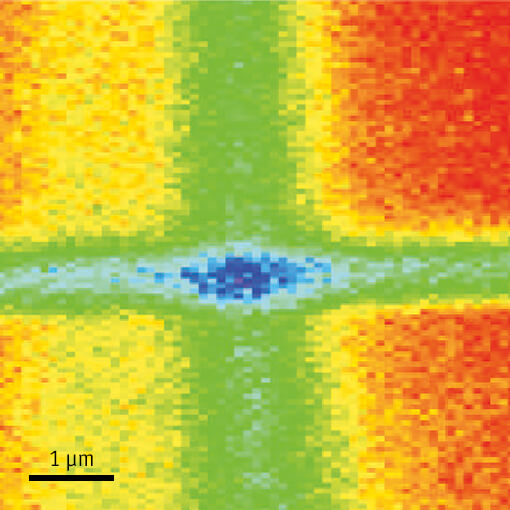

Characterizing a scanning fluorescence X-ray microscope

When developing an X-Ray microscope capable of nm resolution, careful design is a must. Thermal and mechanical stability of the components and assemblies has to be followed throughout the process. The FPS shows superior performance regarding its outstanding stability and its capability of measuring sub-nm displacements. The senor has a better than 1.25 nm stability over 40 hours, and a better then 300 pm resolution at 100 Hz bandwidth in a controlled environment. The FPS is therefore the ideal supplement for the mechanical control of all components used in the described X-Ray microscope setup achieving a resolution in the order of 40 nm, while the stability is below 45 nm over the entire time needed for data collection.

This measurement was realized with the Displacement Measuring Interferometer.

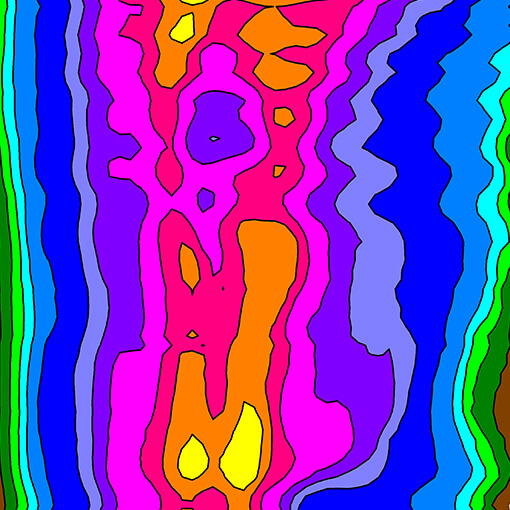

Fiber based laser interferometry stimulating the development of highly precise micro manufacturing

Ultra-precise and contactless surface analyses are of major interest in order to guarantee the quality of the material in many research and industrial applications. The large acceptance angle is one of the main strong benefits of attocube’s Industrial Displacement Sensor (IDS). Due to its proprietary patented techniques, the system allows for measurements on surfaces with more than 10° inclination with respect to the measurement direction. The actual measurement shows nanometer precise 3D profilometry data of micron-sized metal cylinders. Several deformations can be seen: In the center position the object profile clearly shows a dent on its surface with a depth of around 400 nm. In addition the diameter contour in the front part near x = 0 has a plateau over a length of approximately 10 µm.

This measurement was realized with the Displacement Measuring Interferometer.

3D Profilometry of Micrometer-Sized Cylinders

In many research and industry applications, ultra-precise and contactless surface analyses are a key factor in order to guarantee the quality of the material under investigation, as well as to detect even the tiniest contour deviations of the material.

Especially when measuring on micron-sized objects, accurate alignment of the sensor head can be very difficult. With attocube’s fiber-based interferometer and the newly introduced D12/F2.8 sensor head, these measurements can now be performed easily.

This measurement was realized with the Displacement Measuring Interferometer.

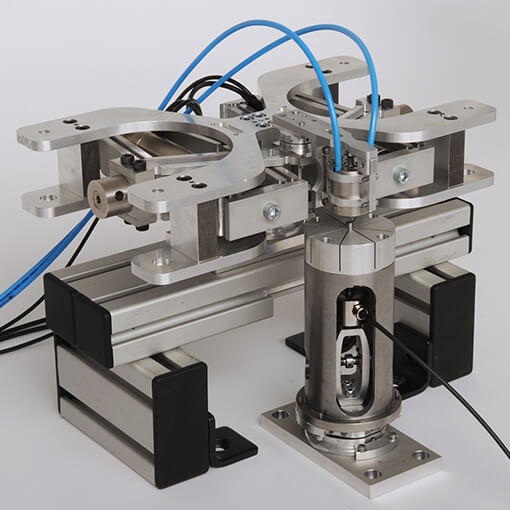

Nanometer Precise Positioning During Sample Rotations

Synchrotrons are electron particle accelerators that provide high-brilliance x-ray beams for experimental end-stations where it is used to study properties of different materials. These x-rays, having high penetration capabilities and highly focused beams, are often used in image scans where motion positioning systems play a primal role.

X-ray nano-imaging necessitates positioning systems with high constraints in mechanical construction as well as position metrology. In-axis and crosstalk motion errors, from linear as well as rotational drives, are always present and notably troublesome at nanometer-precision scans. Rotational drives are particularly difficult to characterize in respect to axial runout and wobble.

This measurement was realized with the Displacement Measuring Interferometer.

Detecting vibration propagation and parasitic motions with picometer resolution

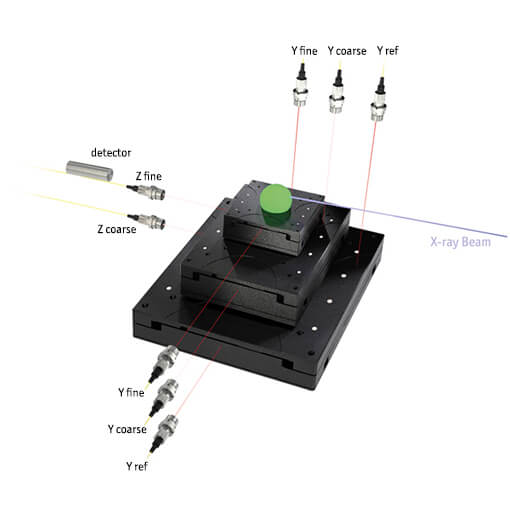

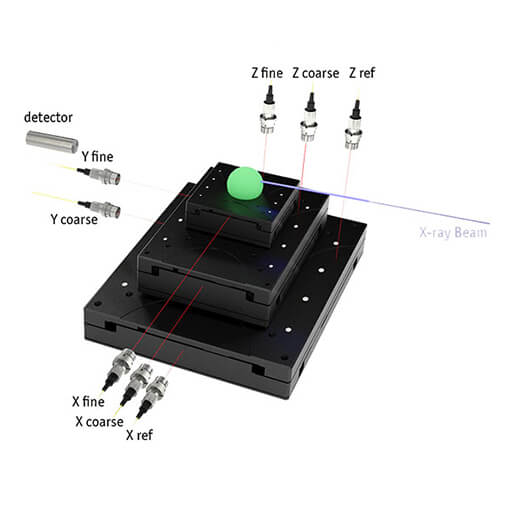

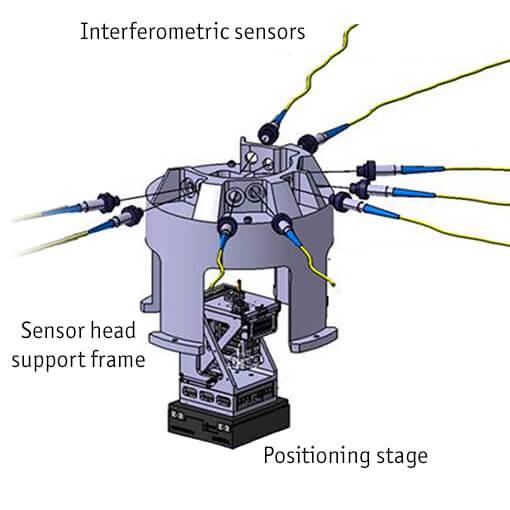

Exact sample positioning in synchrotron beamlines requires position detection with highest resolution. A group at the Diamond Light Source designed a sample positioning system with three positioners for x, y, z movements. To determine the error motions, eight axes of three IDS3010 devices were triggered for synchronous data acquisition, controlling the movement with BiSS-C interface. They identified parasitic motions of only 100 pm that were caused in the non orthogonal fixing of the positioners. These smallest amount of deviation can be detected in Ultra-high vacuum only - and with the IDS3010.

(Trevor Bates, Brian Nutter, Diamond Light Source Limited, Oxfordshire, England)

This measurement was realized with the ECSx5050/Al/RT, and the Displacement Measuring Interferometer.

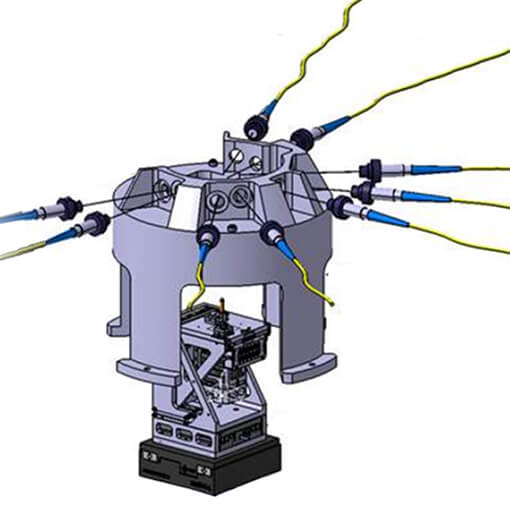

Interferometric Multi-Axis Motion Control of an X-Ray Setup

In high precision systems for moving objects in nanometer ranges, error motions and vibration propagation are crucial information for the motion accuracy. Due to this, synchrotron facilities continue to develop and upgrade different components to keep pace with the latest available technologies. The beamline I08 recently upgraded the end-station using attocube interferometers IDS3010 with BiSS-C interface. An experimental setup at the Diamond Light Source is synchronously triggering and tracking the movement of eight different linear axes. These eight axes were controlled by the Delta Tau “GeoBrick” controller, which ensures the accurate timestamped data from all eight axes, i.e. three IDS3010 devices.

The setup consists of three motion modules as shown in a simplified version in the upper figure: from the bottom one manual positioner, on top of it one stepper motor for more coarse adjustments, and finally on top of that one piezo-based positioner for fine motions. All three modules can move in X-, Y-, and Z-direction, i.e. the complete setup consists of 9 linear movements, and is being tracked by 8-axes consisting of M12/C1.6 high vacuum compatible sensor heads. Since the sample’s position is relevant for each movement of the three modules, every motion axis needs to be tracked. There are two kinds of error motions (parasitic movements) relevant for the sample’s position: vibrations caused by moving the positioner that spread to connecting positioners and the sample, as well as uneven motions caused by non-parallel mountings between the positioners.

One measurement example is shown in the lower figuer, which only involves the X, Y, and Z piezo-based positioners in the upper module. The two parasitic movements are shown while moving the fine piezo positioner in the X-direction using 5 nm step sizes. The red line (X-axis) shows the positioner moving in one direction, after 10 steps, the positioner is moving back with one 50 nm step. The blue line (Y-axis) shows the error motions of the fine positioner orthogonal to the motion of the positioner in the horizontal level. The noised oscillations are caused by vibration propagation emerging from the positioner’s motions. This line shows a linear offset of 10 pm for every step. This offset originates from the not perfect parallel mounting between the X- and Y- positioners. This non orthogonal mount can be compensated using the information for the other axes. The green line (Z-axis) shows the vertical movements of the fine positioner. Only the last step of 50 nm shows a significant change of the vertical position, presumable due to a rapid vibration.

(Diamond Light Source Limited, 2017)

This measurement was realized with the Displacement Measuring Interferometer.

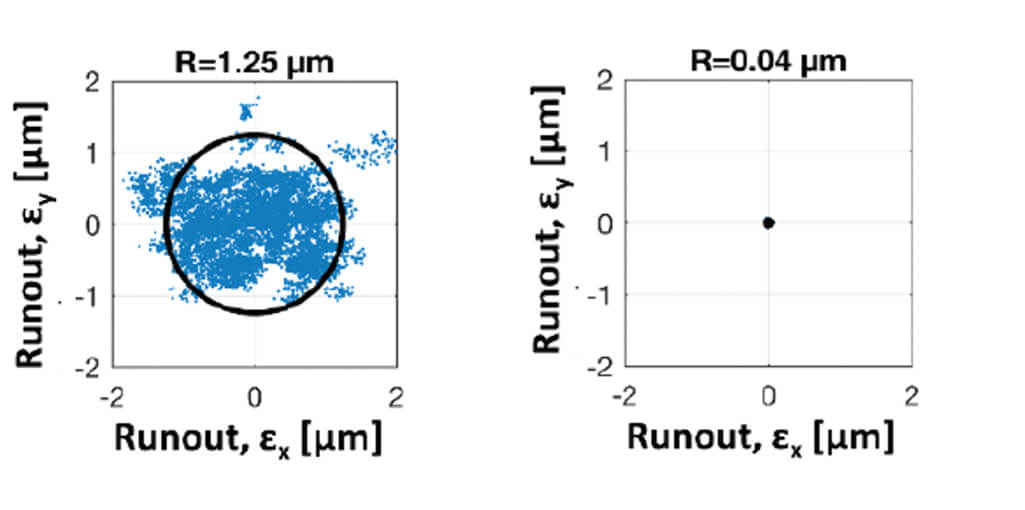

Rotation motion error compensation for stable probe positioning

The challenge of rotatory probe positioning for x-ray nanotomography is the limited tolerance of the runout. The smaller the runout - the better the resolution of experiments. The closed loop system at the synchrotron SOLEIL consists of a positioning stage for rotating the probe and attocube‘s interferometer focusing directly on the rotating cylinder. The positioning stage is equipped with three linear drives, two piezo driven positioners for compensation of error motions, and one rotational stage. Based on a reduction algorithm for error motions, the initial runout of 1250 nm is reduced to 42 nm - a decrease of 97%.

(Christer Engblom, Synchrotron Soleil, St Aubin, France)

This measurement was realized with the Displacement Measuring Interferometer, and the .

OEM Interferometers for motion tracking in coordinate measurement machines

Coordinate measurement machines (CMM) have highest requirements towards precision. CMM determine geometrical dimensions of simple and complex products and components for quality control (e.g., measurements of manufacturing accuracy or tribological measurements). Those applications require an accuracy in a sub-micrometer range, while the calibration and the machine-integrated control need a higher level of accuracy.

The laser interferometers of attocube are solutions providing highest precision and large working distances at the same time - suiting the challenging requirements of CMM. While the IDS3010 allows to measure displacements of up to 5 meters, it simultaneously detects overshoots in the nanometer range. Furthermore, the compact design of the IDS3010 and the sensor heads fits machine-integrated applications.

Customers can choose:

- target velocity up to 2m/s

- direct beam or mirror deflection

- Workings distances of up to 5 meters with a constant precision in nanometer range

- In situ measurements on the touching probe without Abbe errors instead of mechanically transmitted position acquisition (e.g glass-scales)

- Compact interferometer unit for machine-integration

This measurement was realized with the Displacement Measuring Interferometer, and the .

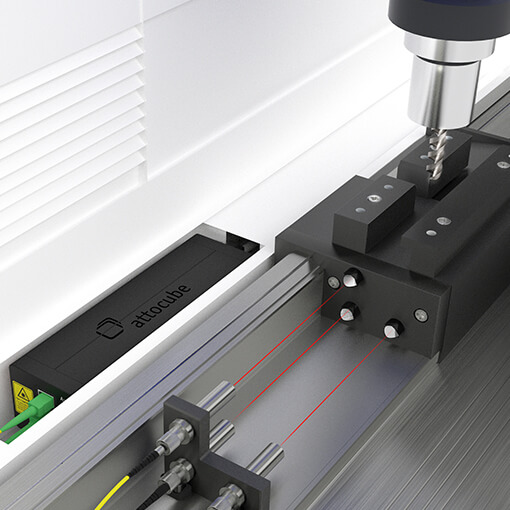

Ultra Precise In-Line Travel Property Control

In many industrial processes, motion and accuracy of motion are of utmost importance. This is true for machining processes (e.g. ultra-precision machining), wafer processing and inspection, metrology measurements, and many other applications.

For this purpose, attocube has designed a three-axis miniature laser interferometer, which provides ultra precise real-time measurement of linear target motion as well as analysis of parasitic pitch and yaw motions. If embedded in a closed loop circuitry, motion in three degrees of freedom can be controlled down to the nanometer scale.

Customers can choose:

- sensor head diameter from 1 mm up to 15.5.mm

- distance sensor head to target from 0 mm to > 1 meters

- target velocity up to 2 m/s

- direct beam or mirror deflection

- customized housing

This measurement was realized with the Displacement Measuring Interferometer, and the .

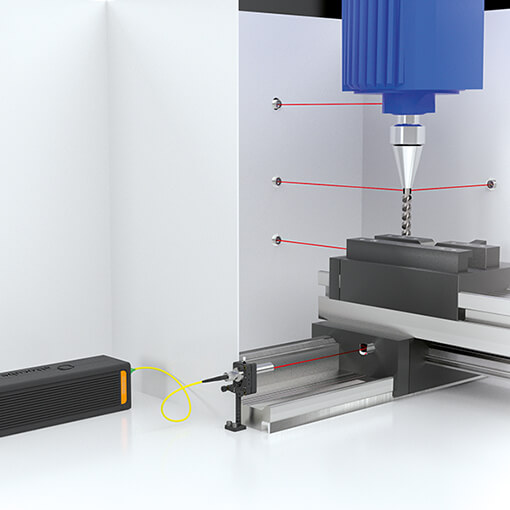

Machine Integrated Sensors for Motion Capturing

The growing demand for high accuracy position sensing in machine tools requests cost efficient yet flexible sensors with high resolution at potentially large working ranges. Up to today, interferometry has been well known for highest accuracy but also high costs and demanding space requirements, making it unattractive for mass application and machine integration.

attocube's IDS3010 now solves this challenge: the ultra compact OEM interferometer is an economic solution and optimized for machine integration with unrivaled optical performance. Especially for applications exceeding the specifications of industry-wide used glass-scales, the IDS3010 is capable of capturing motions more accurate than other measurement systems.

Customers can choose:

- a wide range of interfaces (analog sin/cos, digital incremental, field busses)- various sensor head designs for environments ranging from low temperature to 400°C. sensor head diameter from 1 mm up to 15.5 mm

- distance sensor head to target from 0 mm to > 5 meters

- target velocity up to 2 m/s

- direct beam or mirror deflection

- customized housing

This measurement was realized with the Displacement Measuring Interferometer, and the .

Long distance and high-speed displacement measurements

Machine vibrations induce errors in parts manufacturing. The miniscule vibrations of a milling machine produce erratic motions of the workpiece with regards to the cutter and hence, may lead to contouring errors or a bad surface finish. Such defective parts create problems and can jeopardize the whole system’s assembly or safe operation. In the end, they may fail quality criterions such as the 6-σ standard. Get our latest application note & see how the FPS3010 can help to efficiently and precisely characterize vibrations, thus helping to succesfully eliminate these errors.

This measurement was realized with the Displacement Measuring Interferometer.

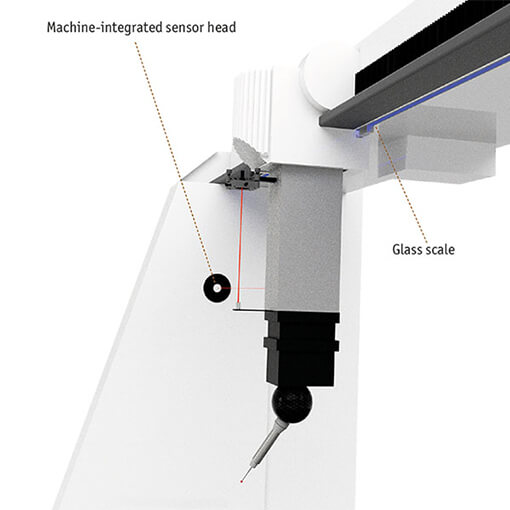

Position Capturing in Coordinate Measurement Machines

Cordinate measurement machines (CMM) measure more than just distances, they are capable of capturing a broad range of geometries: angles, profile of a surface, parallelism, symmetries, tolerances, circularity, and much more. For those applications, CMM provide an accuracy in a sub-micrometer range. To enable this level of accuracy, CMM need even more accurate sensors to be calibrated.

Since glass-scales do not measure the displacements of the touch probe itself, they cannot detect the actual overshoots and motion of the touch probe. Because of the contactless measurement technology, attocube’s IDS (Industrial Displacement Sensor) is capable of focusing on the touch probe directly and capturing the motions at the point of interest.

This measurement was realized with the Displacement Measuring Interferometer.