Fiber Array Alignment with Multi-Axis Piezo Stages

For optical data transmission fibers need to be precisely attached to different components. A wide variety of components is used for optical, photonic and electronic modules, simultaneously their complexity increases. Therefore, it is inevitably necessary to have suitable and reliable products to be one of the leading providers in the field of micro assembling. The fundament for the assembly of photonic devices is particularly precision of multi-axis movements.

Due to the fact that the ECS series stages can be driven in coarse and fine positioning mode the fiber can easily be moved on a mm level to the desired position and then be adjusted on a nm level with highest precision. Piezo driven stages also captivate with long term stability when a specific position needs to be held over an extended time period. The modular design enables multi-axis solutions by simply combining different positioners and types of movements.

This measurement was realized with the ECSx5050/Al/NUM/RT, the ECGt5050/Al/NUM/RT, and the ECR5050hs/Al/RT.

Piezo-based Positioning for Magnetic Field Detection

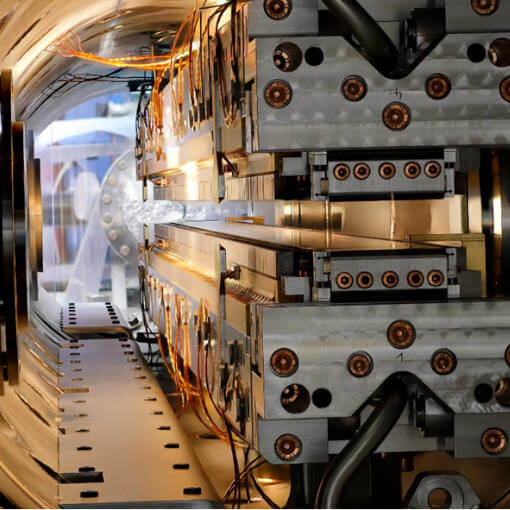

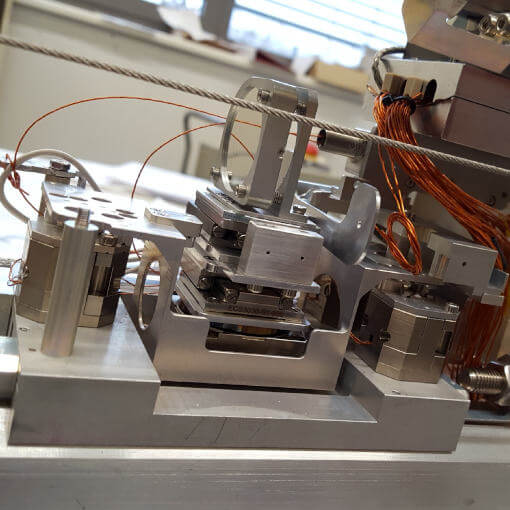

X-rays, also referred as synchrotron radiation, serve as an important tool to observe the structure and dynamics of matter. The radiation is generated by bending magnets, wigglers or undulators. While bending magnet and wiggler radiation have a broader spectrum of photon energies, undulator generates narrow peaks, i.e. bright and coherent radiation at specific harmonics. This specific peak spectrum and defined photon energy is the main advantage of undulator radiation. Dr Carsten Kuhn and his group at the Helmholz-Zentrum in Berlin (Berlin, Germany) developed the new generation of undulators for the storage ring BESSY II. In order to optimize the resulting photon energy, the magnetic properties of cryogenic undulators need to be characterized precisely at different temperatures by movable Hall probes. Therefore, they designed a measurement slide with six attocube positioners to align the hall probe with respect to the undulators' magnets. With this precise analysing setup, the position accuracy of the Hall-probes is at least 5 μm and 20 μrad.

This measurement was realized with the ECSx3030/StSt/NUM/HV, and the ECSx3030/StSt/NUM/HV.

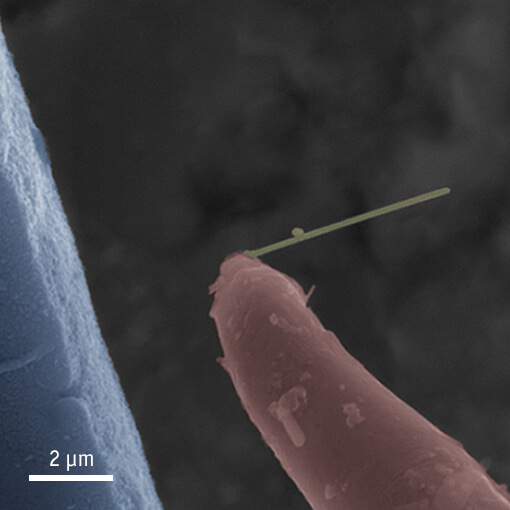

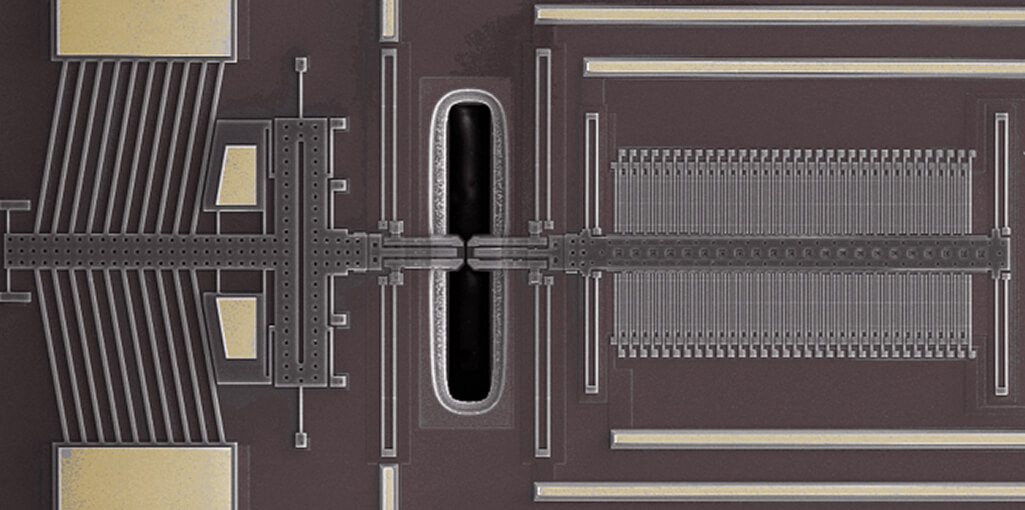

Micromechanical Testing of Silver Nanowires

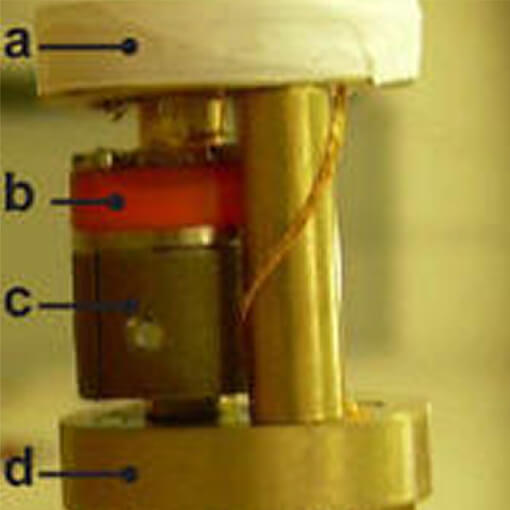

The small size of specimens often imposes significant challenges for preparation and testing. To overcome these difficulties, Prof. Horacio Espinosa’s group at the Mechanical Engineering Department in Northwestern University, USA, has developed a microelectromechanical system that allows mechanical testing of nanowires (see left figure). The system is capable of simultaneous four-point electrical measurements, therefore enabling piezoresistivity and -electricity measurements.

In order to mount the silver nanowires, they employed an attocube nanomanipulator, composed of three stacked ECS3030 positioners, one for each axis of movement. The nanomanipulator is positioned inside an SEM chamber and interfaced to the ECC100 piezo-controller outside the chamber.

This measurement was realized with the ECSx3030/Al/RT.

Further reading:

R.A. Bernal, et al., Small 10, 725 (2014)

Performance Test of the ANPz30/LT at 35 mK and 15 Tesla

The precise performance of nanopositioning elements is of great importance in order to realize instrumental setups which work reliably under extreme environmental conditions. Although attocube systems’ positioners have been tested at low temperatures down to 10 mK and at high magnetic fields up to 28 Tesla, their successful performance has never been demonstrated when both environmental conditions were simultaneously applied. A real challenge, furthermore, is to carry out such a test in a 3He/4He environment due to the fact that 3He carries a magnetic spin which becomes polarized in magnetic fields. This influence on the positioner’s operation was investigated for the first time in this application.

This measurement was realized with the ANPz30/LT - linear z-nanopositioner.

Enabling Haptic Assembly of Micrometer Structures

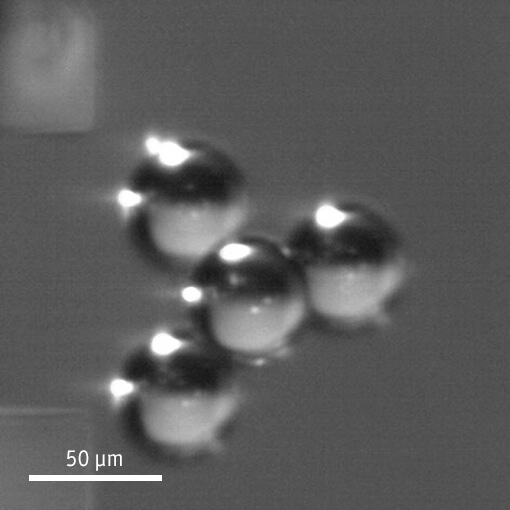

M. A. Srinivasan of MIT, USA and UCL, London, with support from TUM-IAS, Munich, has developed a micromanipulator with an haptic interface to enable manual exploration, manipulation, and assembly of micro-structures. In collaboration with A. Schmid of UCL, London, S. Thalhammer of Helmholtz Zentrum, Munich, and R. Yechangunja of Yantric, Inc., USA, he has demonstrated manual grasping and moving of 10 to 100 µm sized objects with direct haptic feedback of the gripping force in real-time, so that the objects can be placed in three dimensions with nanometer precision.

A force-sensing microgripper with 100 µm opening is mounted on an ANPxyz101/NUM stack of attocube’s closed loop positioners. Measured forces by the microgripper in the micro-Newton range are scaled up and exerted on the operator’s fingers through a haptic interface.

This measurement was realized with the ANPx101/RT - linear x-nanopositioner, and the ECSx3030/Al/NUM/RT.