Your OEM Partner for Nanoscale Solutions

custom engineering, manufacturing & integration of motion and sensing components

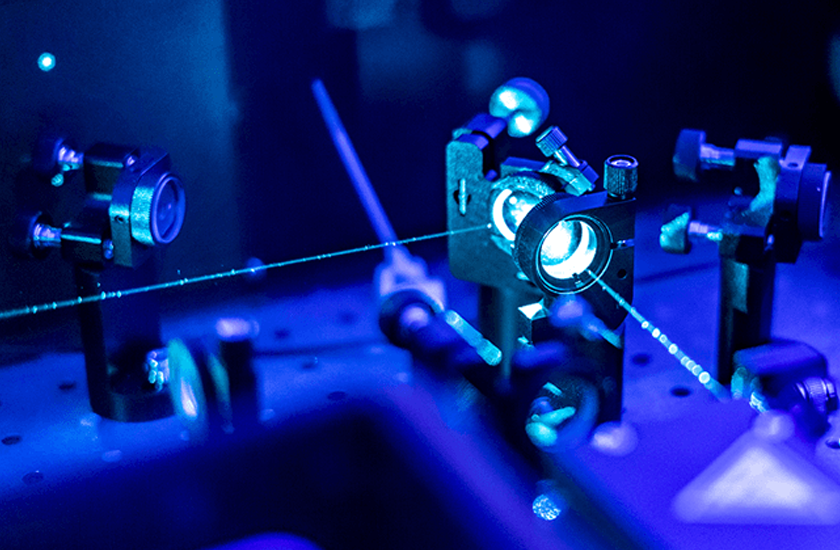

attocube nanopositioners and laser interferometers offer component, module, and systems levels of integration supporting OEM partners in providing cutting-edge products. The high precision and compactness of the products make them easy to integrate into space-confined applications.

The OEM-ready supply chain ensures a quick turnaround, stable quality, and long-term reliability. A highly qualified application and development team helps to optimize products for the specific customer requirements and markets.

High Precision Motion & Sensing Components for

Engineering Competence for your Application

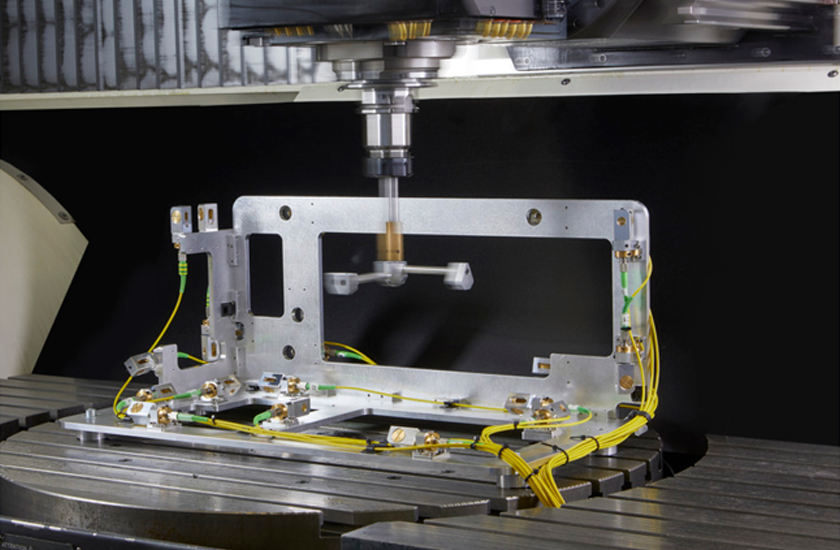

High precision applications have specific requirements concerning certification, travel range, or clean room compatibility. Since standard products typically cannot account for these variations, attocube offers a broad range of customized components and sub-modules as well as integrated systems solutions.

Combining competencies in nano-positioning and interferometry, attocube's customizations enable best-fitting customer solutions and realization of applications that push the limits of the technical feasibility.

1. Conception

Collection and definition of requirements with our customers and partners.

2. Refinement

Optimization of requirements and system architecture to offer a solution concept.

3. Design

Detailed design and prototyping by experienced technology experts.

4. Test

Testing and verification under application conditions (e.g. HV/UHV/extreme temperatures).

5. Launch

Integration, installation, and operation support.

Your Reliable OEM Partner

From Research to Industry

Having its roots in the field of scientific analysis and being a market leader for nanotechnology in research, attocube works shoulder to shoulder with today’s technological pioneers. With the core competence for converting highly complex scientific devices into user-friendly industry products, attocube identifies future trends early and always provides cutting-edge technology, pushing the boundaries of what is currently considered technically feasible.

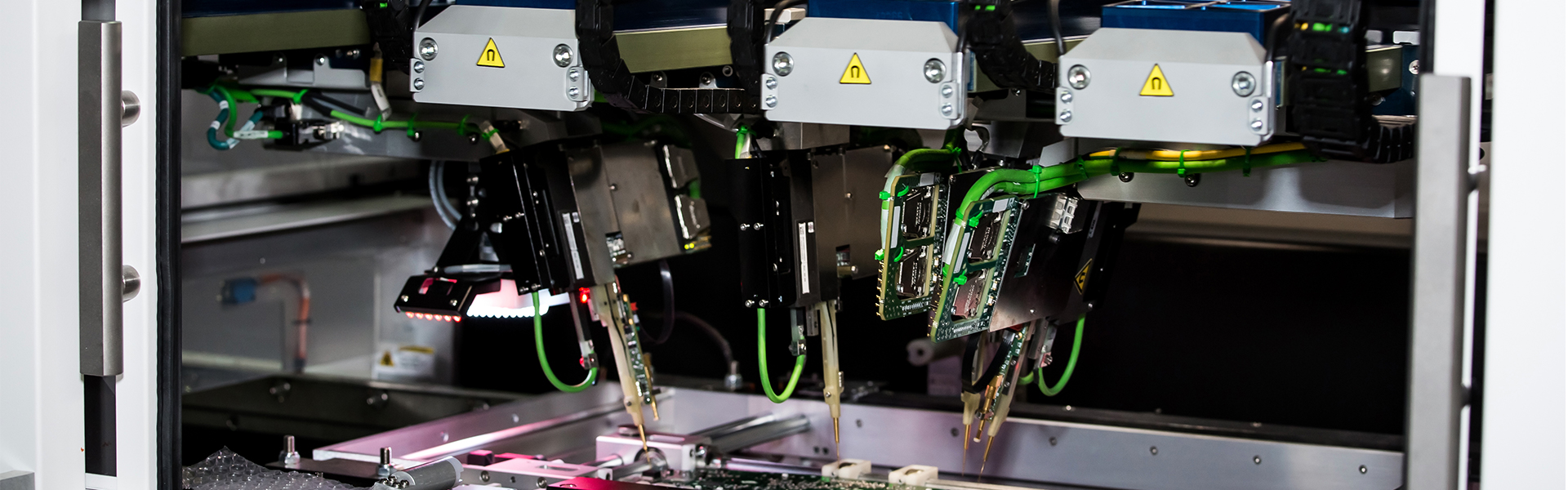

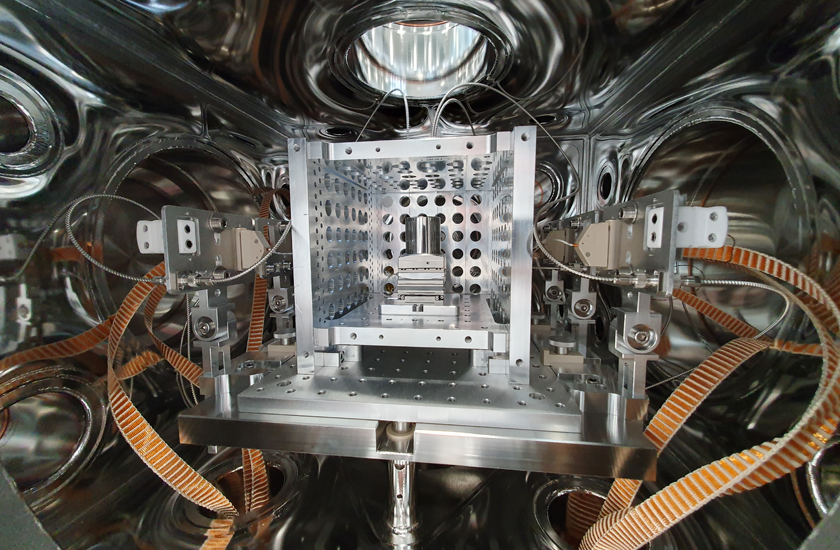

Testing Facilities & Quality Assurance

attocube designs, tests, and offers components for extreme environments. The quality assurance is equipped with test stations for high or ultra high vacuum, as well as low or elevated operating temperatures. This ensures to fulfill industry quality standards and offer application tailored testing procedures.

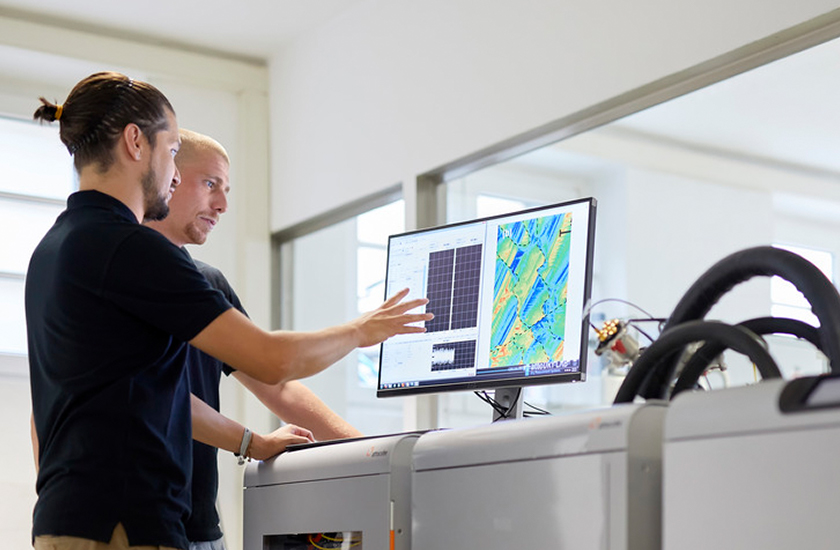

Application Development & Expert Support Team

attocube's application team consists of experts from metrology and precision engineering who help customers in selecting, integrating, and testing suitable solutions for their systems.

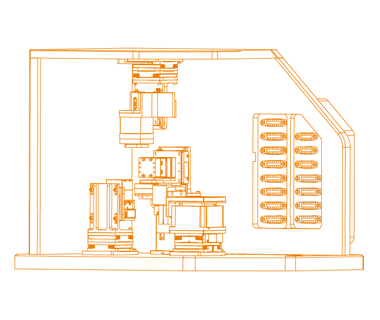

Lean Production & Shopfloor Management

The entire supply chain is orientated towards lean production, which enables short delivery times, flexibility, and high quality for the production of customized systems as wells as large quantities. attocube's manufacturing engineers enable customer specific adaptions of production procedures to meet all product and process requirements.

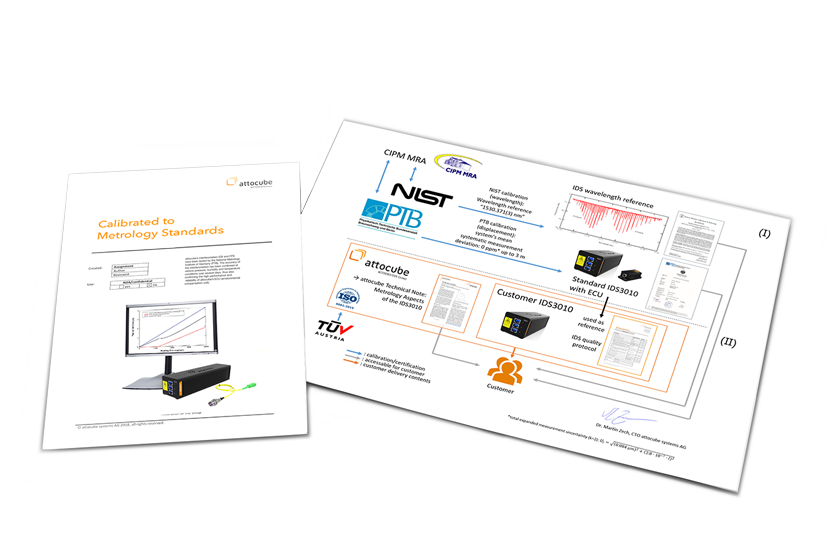

Traceability of Sensing & Motion Components

attocube's sensor technology is NIST and PTB traceable, enabling Motion & Sensing systems that are calibrated to metrology standards. The sensors used in attocube's production facility are calibrated directly by PTB or in DAkkS-accredited laboratories.